Manufacturing Process

Where Precision and Passion Converge

At Fashion Soul International, we bring your vision to life with a meticulously organized manufacturing process that seamlessly combines advanced technology, skilled craftsmanship, and eco-friendly practices. Every garment we produce follows a precise series of steps, each designed to ensure the highest quality standards. Here’s a closer look at our end-to-end Manufacturing Process.

1️⃣ Pattern Making & Fabric Cutting

📐 Accuracy at the Core

Pattern making starts the manufacturing process by turning the garment design into a detailed blueprint. Our advanced CAD software enables us to develop precise digital patterns that follow your tech pack specifications. After patterns reach completion our team begins fabric cutting using both manual methods and automated equipment to achieve accurate fabric pieces. Our cutting techniques enable garments to maintain precise shapes while reducing waste and supporting environmental sustainability.

Technology & Expertise: Advanced cutting machines and expert operators work together to deliver perfect cuts while conserving fabric material.

Eco-friendly Sourcing: Our fabric selection process focuses on sustainable materials to lessen environmental damage.

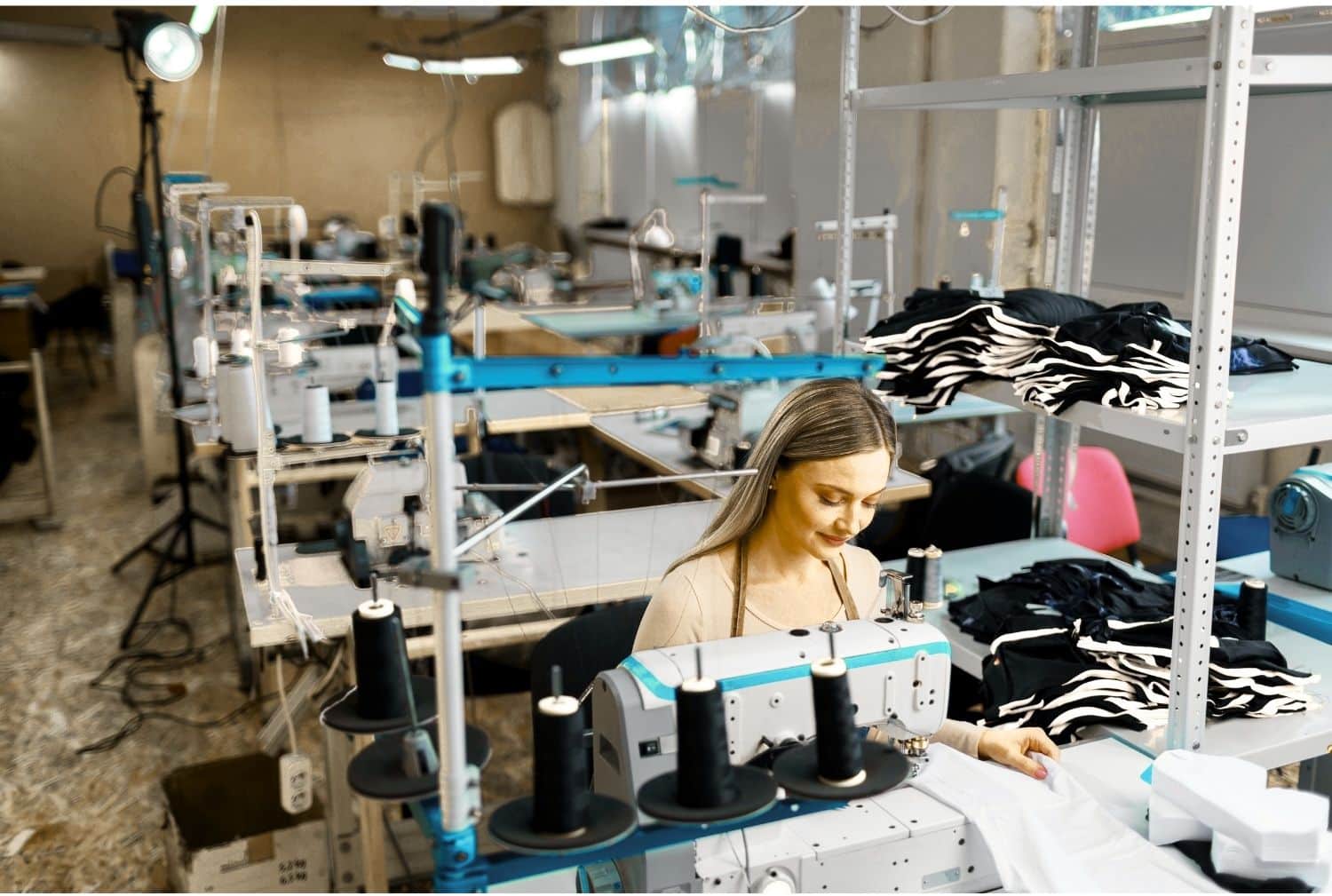

2️⃣ Sewing & Garment Assembly

🧵 Crafting Your Vision into Reality

The cut fabric pieces undergo multiple sewing operations performed precisely for constructing a high-quality garment. Our stitching methods vary depending on both the garment type and fabric material because we employ specialized stitching techniques such as:

Flatlock Stitching creates seamless designs specifically for sportswear and activewear products.

Overlock Stitching for neat and secure finishes

Cover Stitching for stretch garments and hems

Heavy fabrics benefit from increased strength thanks to Double Stitching.

Our custom sewing techniques such as embroidery and laser cutting create unique features on your garments to align with your distinct brand identity.

3️⃣ Washing & Dyeing (If Applicable)

💦 Enhancing Quality & Feel

Our process includes applying washing and dyeing treatments after sewing to reach the required appearance and texture for certain fabrics and designs. Some of the processes we use include:

Stone or Acid Washing for vintage effects

Garment Dyeing for a bold, uniform color

Enzyme Washing to soften the fabric

The application of silicone softening results in fabric with smooth and luxurious texture.

Our dyeing and washing processes are designed to be environmentally friendly which results in a reduced environmental impact for your garments. Our processes follow OEKO-TEX® Standard 100 alongside other industry standards to provide both chemical safety and sustainable production.

4️⃣ Embellishment & Customization

🎨 Bringing Your Brand to Life

Screen printing alongside embroidery, heat transfer, and sublimation printing serves as the core elements to create unique garments. Our services cover every aspect of customization including your logo, design work, and slogan application.

Embroidery: Our advanced embroidery machines enable us to apply custom designs including logos and detailed patterns onto fabric.

Screen Printing & Heat Transfer: We apply water-based inks with sustainable transfer methods to create large designs and detailed patterns.

Sublimation Printing: This printing method provides vibrant and durable prints specifically suited for polyester-based materials.

Our thorough inspection process evaluates every embellishment for proper alignment and consistency to uphold quality standards that reflect your brand’s identity in all details.

5️⃣ Quality Control & Inspection

🔍 Rigorous Checks to Ensure Excellence

Fashion Soul International maintains a commitment to quality throughout all stages of production. Through our multi-level quality control process we guarantee that all garments reach your brand while meeting top quality standards. Our quality checks include:

In-line Inspections: The manufacturing process includes inspections to identify defects at an early stage.

Mid-line Inspections: Conducted after key components are assembled

Final Inspection: The final inspection stage involves a comprehensive AQL (Acceptable Quality Level) assessment which examines the finished product for potential stitching problems, fabric defects and sizing irregularities.

Items that fail to satisfy our quality standards face immediate identification for thorough examination and correction.

6️⃣ Finishing, Ironing & Folding

🎁 Perfecting Every Detail

The garment enters the finishing stage immediately following the final inspection approval. This step involves:

Steam Pressing: Each garment undergoes steam ironing to eliminate wrinkles and achieve a polished clean finish.

Thread Cutting: We eliminate all loose threads to achieve a polished professional appearance.

Folding & Packaging: We fold garments according to pre-set specifications like flat fold or hanger pack based on your requirements before preparing them for packing.

Premium brands benefit from our special packaging alternatives which include custom-made hangtags alongside eco-friendly bags and luxury gift boxes.

7️⃣ Global Dispatch & Shipping

🌍 Ready to Ship Across the Globe

After your garments are packed they become available for shipment. Our partnership network includes top international logistics companies like DHL, UPS, FedEx, and Maersk to provide secure global delivery. Our team handles every aspect from door-to-door delivery through customs documentation to ensure seamless international shipping.

You can monitor your shipment status through our real-time tracking service.

Why Choose Our Manufacturing Process?

Fashion Soul International takes pride in delivering the following services:

Fashion Soul International allows customers to order in small batches or large quantities because of our low Minimum Order Quantities (MOQ).

Our manufacturing process incorporates sustainability through eco-friendly practices along with water and energy preservation as well as waste management strategies.

Our services allow complete customization of fabric choices as well as design styles and color selections along with packaging options.

Our products achieve certified quality status through adherence to globally recognized standards such as ISO, REX, Sedex and OEKO-TEX®.

A Wide Range of Products We Offer.

FAQs

Frequently Asked Questions

1. What materials do you use in garment manufacturing?

We use eco-friendly and certified fabrics such as organic cotton, recycled polyester, bamboo blends, and sustainable materials. All fabrics meet international quality and safety standards.

2. How long does the manufacturing process take?

The production time depends on order size, design complexity, and customization. Standard lead time is 2 to 6 weeks from pattern making to delivery.

3. Do you offer fully custom garment designs?

Yes, we offer full customization including fabric selection, colors, patterns, trims, and labeling. We also produce custom samples before bulk production to ensure quality and design accuracy.

4. What quality control steps do you implement?

We perform strict quality inspections at every stage — in-line, mid-line, and final AQL inspections. Any defects found are corrected before packaging and shipment to ensure high-quality products.