Woolen fabric is an ancient textile that has lasted for so many years. It is soft, warm, and extremely adaptable which made it a favourite for many years. From keeping people warm in the cold winters to boasting rich decor in houses, woolen fabric has always been useful. But what is woolen fabric? What is its manufacturing process, and what makes it unique? This detailed article will provide an insight into woolen fabric’s features, numerous applications, and manufacturing processes.

Table of Contents

Introduction to Woolen Fabric

Woven woolen fabric uses untreated natural wool fibers and features a soft, fuzzy texture. Manufacturers form of the fabric from a sheep’s sheared fleece and often incorporate fibers from alpacas, goats (like cashmere and mohair), and rabbits (primarily angora). The carding process makes woolen fabric unique by keeping the fibers somewhat unsymmetrical, which gives the fabric its bushy, warm, and airy feel. Wool fabric has preserved the wool’s qualities of expansiveness and regain, unlike its cousins like worsted wool which is fabric cloth that can be dry, clean, and fall flat. As a result, woolen woven fabric is very comfortable and highly insulative, making it perfect for many clothing and textile applications. Woolen fabric has changed during the years in both its methods of production and areas of use and has deservedly earned the title of an essential material in the textiles sector.

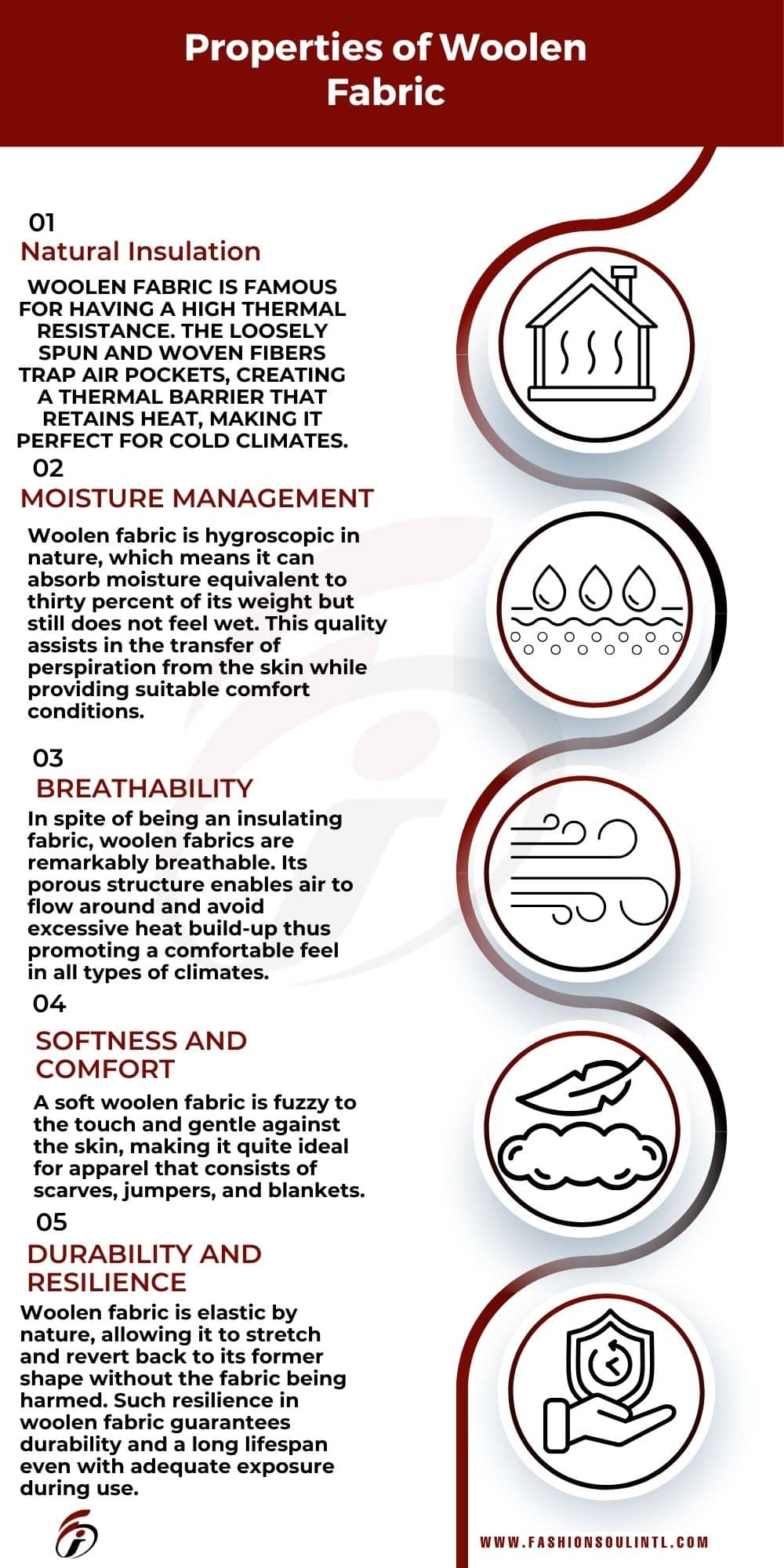

Key Properties of Woolen Fabric

The distinguishing quality of this fabric is probably the extraordinary combination of its functional and physical characteristics. Such features contribute to its efficiency and are also the reason for its wide applicability. Let’s explore its major features in detail:

Natural Insulation

This fabric is famous for having a high thermal resistance. The loosely spun and woven fibers trap air pockets, creating a thermal barrier that retains heat, making it perfect for cold climates.

Moisture Management

This fabric is hygroscopic in nature, which means it can absorb moisture equivalent to thirty percent of its weight but still does not feel wet. This quality assists in the transfer of perspiration from the skin while providing suitable comfort conditions.

Breathability

In spite of being an insulating fabric, woolen fabrics are remarkably breathable. Its porous structure enables air to flow around and avoid excessive heat build-up thus promoting a comfortable feel in all types of climates.

Softness and Comfort

A soft fabric is fuzzy to the touch and gentle against the skin, making it quite ideal for apparel that consists of scarves, jumpers, and blankets.

Durability and Resilience

this fabric naturally stretches and reverts back to its original shape without suffering any damage. This resilience ensures that woolen fabric remains durable and maintains a long lifespan, even with regular use.

Fire Resistance

Wool naturally resists fire, which makes fire resistance one of the most significant advantages of this fabrics. It ignites only at higher temperatures compared to synthetic fibers and extinguishes itself automatically as soon as you remove the flame source.

Odour Resistance

It has the property of being odour-free. The architecture of the woolen fibers hinders the proliferation of bacteria, and it remains fresh even after prolonged wear.

Eco-Friendly and Biodegradable

As a natural fiber, this fabric is renewable and biodegradable. It decays more quickly than synthetic textiles, which makes it an ecology-friendly option.

Such properties make this fabric a more useful material suitable for clothing, home accessories, and also industrial use.

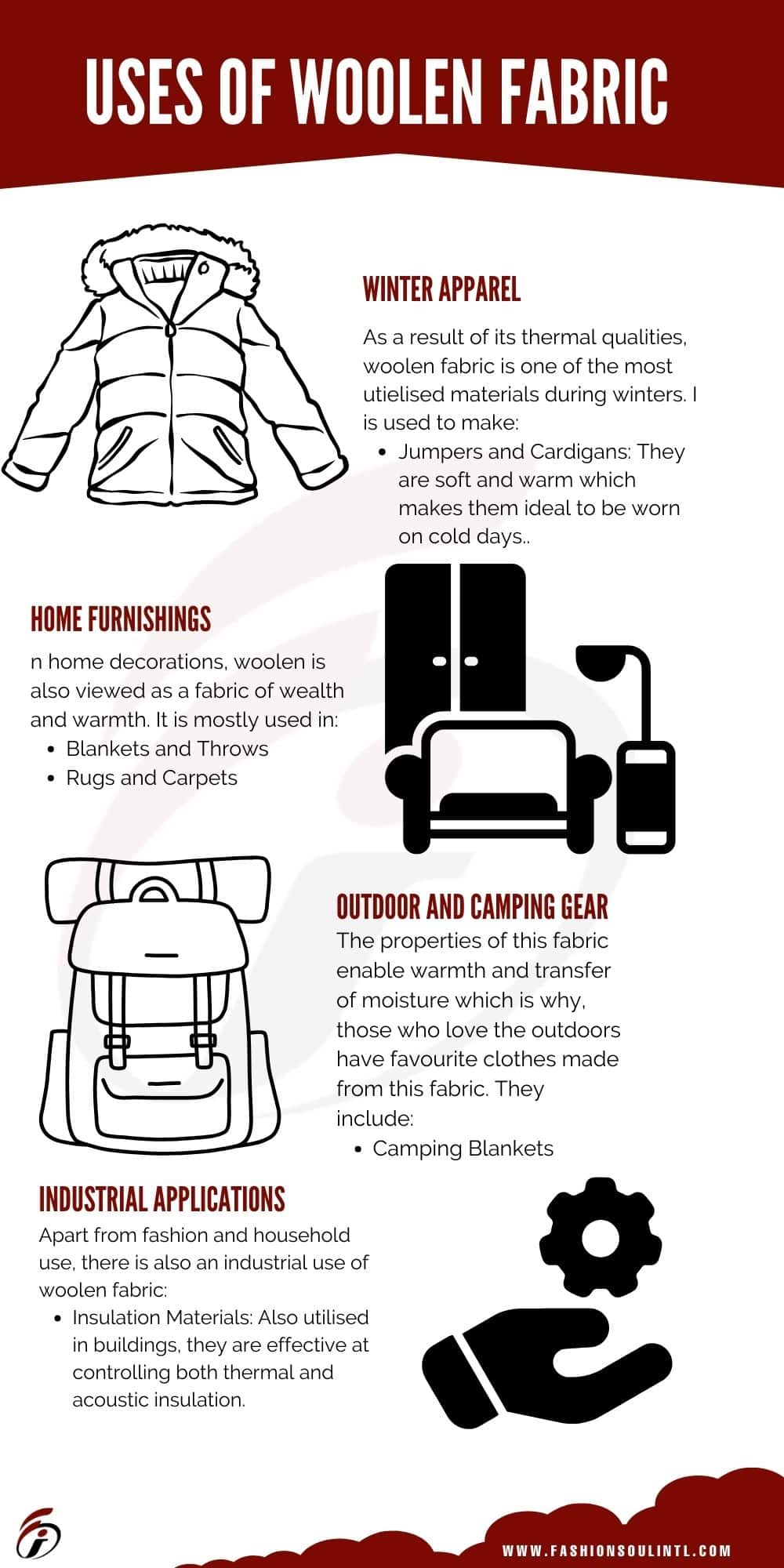

Common Uses of Woolen Fabric

Another word to describe woolen fabric is versatility, as this fabric can meet nearly any requirement. It ranks among the most productive materials and serves many purposes across functional, aesthetic, and technical fields. Below, we discuss some of the common uses of this fabric:

Winter Apparel

Thanks to its thermal qualities, fabric becomes one of the most utilized materials during winter. Manufacturers use it to make:

- Jumpers and Cardigans: These pieces feel soft and warm, making them perfect for cold days.

- Coats and Jackets: These winter garments combine elegance, beauty, and warmth.

- Hats, Gloves, and Scarves: These additional accessories help people stay cozy and stylish during the winter season.

Home Furnishings

People often view woolen fabric as a symbol of wealth and warmth in home decorations. They mostly use it in:

- Blankets and Throws: This is an excellent fabric for blankets especially when one wishes to wrap around them during cold weathers.

- Cushions and Upholstery: This fabric also make the furniture classy and cosy as it improves the grasp and touch of the furniture.

- Rugs and Carpets: The two remain fashionable and practical patterns in the background of interiors.

Outdoor and Camping Gear

The properties of this fabric enable warmth and transfer of moisture which is why, those who love the outdoors have favourite clothes made from this fabric. They include:

- Camping Blankets: Exploring the outdoors is fun but can be dangerous without the right tools. Camping blankets can save lives during emergencies.

- Wool Lined Boots and Jackets: As most camping blankets are bulkier, jackets ready for outdoor activities such as hiking and trekking.

Industrial Applications

Apart from fashion and household use, there is also an industrial use of this fabric:

- Insulation Materials: Also utilised in buildings, they are effective at controlling both thermal and acoustic insulation.

- Safe Work Practice: Fire retardant woolen fabric is incorporated into protective clothing.

Crafts and DIY Projects

This fabric is a well-liked fabric in crafting as it is versatile. It is employed in the manufacture of:

- Toys and Decorations out of Felt

- Purses and other such industrially produced items along with their accessories

These uses demonstrate the diversity of woolen fabric and its contribution in various fields.

The Step-by-Step Manufacturing Process of Woolen Fabric

The crafting process behind the woolen fabric is quite comprehensive as it is a combination of the old and the new. Each step has the objectives of producing the trademark softness, warmth, and the strength of the fabric. Elaborated below is the detailed description of the manufacturing procedure:

Wool Harvesting

The first step includes cutting the wool from the sheep by strippers who are professionals and carry the procedure out in a humane manner.

Sorting and Grading

After the shearing of wool, it is afterwards sorted and graded. The finer fibers go into the premium woolen fabric while coarser ones go into industrial applications.

Cleaning and Scouring

Wool grease, dirt and vegetable matter are other impurities that can be found on the raw wool. The scouring procedure uses warm water and detergent to wash wool to eliminate impurities.

Carding

It is hard to talk about this fabric production without mentioning carding. After scouring, workers feed the wool into contra-rotating carding machines. These machines loosen and arrange the fibers through their carding movement. This process produces a fluffy mat known as ‘sliver,’ which eventually transforms into woolen yarn.

Spinning the Yarn

In spinning operations, workers combine slivers to produce coarse woolen yarns that retain a normal twist. They then spin these slivers on spinning machines to create yarn. The major difference between worsted and woolen yarn is that woolen yarn always has a slack twist and a rough texture to preserve fiber bulk and insulation.

Plotting the Portion

A loom weaves the spun yarn into fabric. The weaving process changes depending on the ultimate goal for the fabric, but woolen fabric generally features a relatively loose, open weave.

Fulling and Finishing

Fulling is the labour-saving step that involves washing and then shrinking of the woven fabric with the intention of tightening the weave. Other additional finishing treatments like brushing-steaming or dyeing improve the aesthetics and texture of the fabric.

Quality Stage of Production and Packaging

As a last step, workers thoroughly check the completed fabric for any possible flaws to ensure it meets industry standards. They then pack and transport it to either a manufacturer or a retailer.

Read more about Denim Fabric and Fleece Fabric

Woolen Fabric vs. Worsted Wool: Key Differences

Although both these textiles are derived from wool fibres, it is evident that all these textile types are dissimilar in their structure, appearance and their end use. The two forms of wool textiles under discussion include:

- Woolen Textile:

It is made from carded wool, in which some short fibres are coarsely twisted.

This fabric is soft, fluffy and ideal for use in warm casual clothing as well as blankets.

- Worsted Wool:

This textile is made of combed wool consisting of longer fibres which are closely twisted.

Fabric from these wool fibres has a smooth finish and is commonly used to make formal clothing such as suits and trousers.

The particular type of fabric also determines which feature predominates, either warm and comforting woolen fabric or aesthetically elegant worsted wool.

Advantages of Woolen Fabric

Woolen fabric has several benefits which have kept it relevant in the textile industry over the years:

- Retains Warmth best: Best for winter.

- Environmentally Safe: Natural and decomposable.

- Wide Range of Use: Can be used in many ways.

- Strong: Tough and long lasting.

- Humidity Control: Stays dry and cool.

These advantages combine to ensure that woolen fabric is a classic material which has a place in modern times.

Challenges in Producing Woolen Fabric

There are several disadvantages that are associated with the production of this fabric which regardless of its many merits remains a difficult task.

- Labour–Intensive Process: Production is time consuming as every step involves skill and precision.

- Cost of Production: Manufacturing costs are increased by the use of quality wool and processing materials.

- Maintenance Needs: In order to keep certain feel and properties, this fabric requires specific care.

Solving these problems is vital for the preservation of the industry that makes this fabric.

Sustainability of Woolen Fabric

With the recent advent of green practices in the modern world, wool fabric comes out on top as an environmentally friendly textile. Wool is a renewable resource as sheep only shed their fleece once a year with no injury. In addition, woolen fabrics are biodegradable which gives them an additional advantage over many synthetic textiles that can take many years before they finally disintegrate.

There are also ethical concerns regarding the shearing of sheep for wool and how this wool industry affects the environment. This conundrum has already been solved with the introduction of certifications like Woolmark that ensure organic production and high quality.

Caring for Woolen Fabric

In order to maintain the good qualities of this fabric, proper care must be exercised. The following tips are advisable:

- Hand Wash or Gentle Cycle: Harsh detergents can damage the fabric, therefore only use ‘wool safe’ soaps.

- Avoid Heat: High temperature wash cycles and tumble drying are not suitable for this fabric.

- Air Dry Flat: It is advised to keep items flat while drying to avoid stretching issues or misshaping.

- Store Properly: Woollen goods should never be out of reach of moths; therefore, moth-proof storage bags should be used in the height of summer.

- De-Pill Regularly: Pilling should be avoided and for that, a fabric shaver must be employed.

Conclusion

This fabric shows us why natural textiles are the way to go. Its warm, cozy, and versatile properties bring it into common use in fashion, household design, and manufacturing. People often mistreat woolen saris, wearing them more than desired, leaving the old woman longing for the elegance of silk. Woven with frost and flakes embedded in it, woolen fabric reaches our bodies in many forms and seduces with a silk-like and satin-like touch. So, grab some warm woolen blankets or sweaters—they serve many purposes, including outsmarting others in games. Just don’t let it flake! Read more about Spandex Fabric.

FAQs

What is woolen fabric made of?

Woolen fabric is made from carded wool fibers, typically derived from sheep’s fleece.

What makes woolen fabric warm?

The loose weave and natural crimp of wool fibers trap air, creating insulation that retains body heat.

How is woolen fabric different from worsted wool?

Woolen fabric has a soft, fuzzy texture, while worsted wool is smooth and tightly woven.

Woolen fabric is made from carded wool fibers, typically derived from sheep’s fleece.

The loose weave and natural crimp of wool fibers trap air, creating insulation that retains body heat.

Woolen fabric has a soft, fuzzy texture, while worsted wool is smooth and tightly woven.