Ripstop fabric is a lightweight material designed for strength and durability. Manufacturers treat it to withstand wear and tear, making it ideal for outdoor gear, protective clothing, and various industrial applications. Its reinforced weave prevents tears and rips from spreading while maintaining flexibility. This article explores the characteristics of fabric, its production process, and its most common applications.

Table of contents

- What is Ripstop Fabric?

- Properties of Ripstop Fabric:

- How Ripstop Fabrics is Made

- Uses of Ripstop Fabric in Outdoor Gear

- Uses of Ripstop Fabric in Apparel

- Everyday Uses of Ripstop Fabric

- Understanding the Types of Ripstop Fabric:

- Types of Ripstop Fabric Based on Material

- What is Gabardine Fabric?

- What is Batiste Fabric?

- Advantages of Ripstop Fabric:

- Conclusion

- FAQS

What is Ripstop Fabric?

The fabric uses a special weaving technique that adds thicker threads at regular intervals to a lighter-weight base fabric. This design creates a unique grid pattern that gives the fabric its tear-resistant strength. During World War II, manufacturers originally developed ripstop fabric to make durable military parachutes. Today, it has become widely used in many commercial applications due to its strength and versatility.

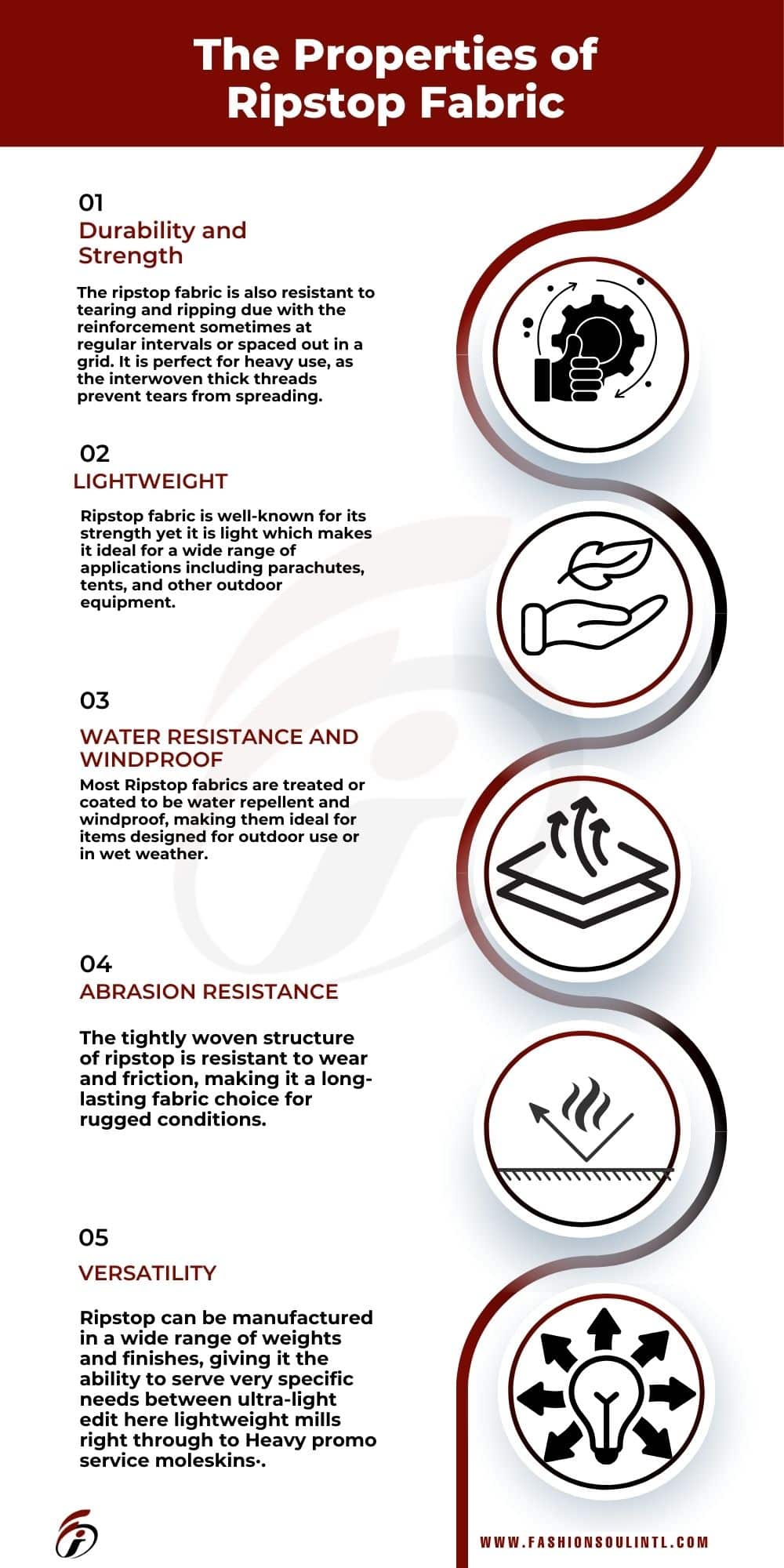

Properties of Ripstop Fabric:

Durability and Strength

The fabric is also resistant to tearing and ripping due with the reinforcement sometimes at regular intervals or spaced out in a grid. It is perfect for heavy use, as the interwoven thick threads prevent tears from spreading.

Lightweight fabric

Ripstop fabrics is well-known for its strength yet it is light which makes it ideal for a wide range of applications including parachutes, tents, and other outdoor equipment.

Water Resistance and Windproof

Manufacturers treat or coat most ripstop fabrics to repel water and block wind, making them perfect for outdoor gear and items used in wet weather.

Abrasion Resistance

The tightly woven structure of ripstop is resistant to wear and friction, making it a long-lasting fabric choice for rugged conditions.

Flame Retardancy (Optional)

Some Ripstop types are flame-resistant (by means of chemical treatment), making them safer for use in the industrial field or for firefighting.

Versatility fabric

Manufacturers can produce ripstop in a wide range of weights and finishes, tailoring it to meet specific needs. It can range from ultra-lightweight fabrics created by specialized mills to heavy-duty moleskins designed for robust promotional use.

How Ripstop Fabrics is Made

Material Selection

Using strong fibers such as nylon, polyester or cotton, manufacturers create a base product. Making it more functional as synthetic fibers are normally mixed with natural fibers.

Weaving Process

Ripstop fabrics uses a plain weave as its base, with thicker threads added at regular intervals to create a grid pattern. This grid strengthens the fabric by stopping small tears from spreading. The reinforcement threads run horizontally and vertically, spaced about 5 to 8 mm apart. To keep the fabric lightweight, very fine threads are used in the base weave, and leftover materials are sometimes woven in. This combination of strength and lightness makes ripstop fabric highly durable and practical for many uses.

Finishing Treatments

Manufacturers finish ripstop fabric to improve its properties. They add a coating of polyurethane (PU) or silicone to make the fabric water-repellent, helping it resist moisture. To protect against sun damage, they apply special coatings that block harmful UV rays. For flame retardancy, chemical treatments are used to make the fabric resistant to fire, ensuring safety in high-risk environments. These finishes make ripstop fabric versatile and suitable for a wide range of uses.

Quality Testing ripstop

The laminated fabric is now tested for strength, stretchability and tear resistance to ensure it passes industry tests.

Uses of Ripstop Fabric in Outdoor Gear

Camping and Hiking Equipment

Outdoor enthusiasts favor ripstop fabric for its reliability and durability. Manufacturers extensively use it in tents, backpacks, and hammocks, where its tear-resistant properties ensure safety and longevity. For example, a ripstop tent withstands wind, rainfall, and ground obstacles, making it a dependable choice for outdoor adventures.

Parachutes and Paragliders

Manufacturers use ripstop fabric for parachutes and paragliders because of its lightweight nature, ease of handling, and resistance to tearing. Most importantly, it remains intact and does not sag, even under enormous strain.

Sleeping Bags

Ripstop fabric is commonly used to make sleeping bags designed for harsh conditions, keeping wearers warm in challenging environments. These sleeping bags are highly durable, able to withstand the demands of many outdoor trips.

Uses of Ripstop Fabric in Apparel

Outerwear and Jackets

Ripstop fabric’s water-resistant and windproof properties make it a popular choice for windbreakers, rain jackets, and coats. These characteristics make it ideal for outdoor apparel.

Military and Tactical Gear

For a long time, military uniforms and other types of tactical gear have made use of ripstop fabric. It allows great durability while being lightweight for ease of movement during combat situations.

Sportswear ripstop

Manufacturers use ripstop fabric in sportswear to produce shorts and lightweight track pants. Its durability and resistance to wear make it ideal for high-impact sports.

Everyday Uses of Ripstop Fabric

Reusable Shopping Bags

Ripstop fabric shopping bags can help impact a sustainable solution and are environmentally friendly and lightweight. They can hold a heavy load without tearing, thus eliminating unnecessary wastage.

Interior Decor

Cushion covers and furniture upholstery are other areas where ripstop fabric is applicable. As it has a high wear and tear resistance, these products are durable and aesthetically pleasing.

Kites and Kiteboarding Equipmen

Another potential application for ripstop fabric would be kites and other kiteboarding equipment. It is important due to its lightweight and its design which consists of tear resistant materials, allowing it to perform well in windy conditions.

Medical Applications

The material is used in medical tents or emergency shelters where required. Its durability and strength of the material gives a temporary solution which is reliable.

Understanding the Types of Ripstop Fabric:

Ripstop fabric is a type of durable fabric with increased strength and tear resistance. It finds its’ application in different fields such as outdoor equipment, apparel manufacturing and even aerospace applications. However, not every ripstop fabric is similar. Certain materials can be used in various industries as they have been made with various properties and characteristics. This guide investigates the various types of ripstop fabric and their features and applications.

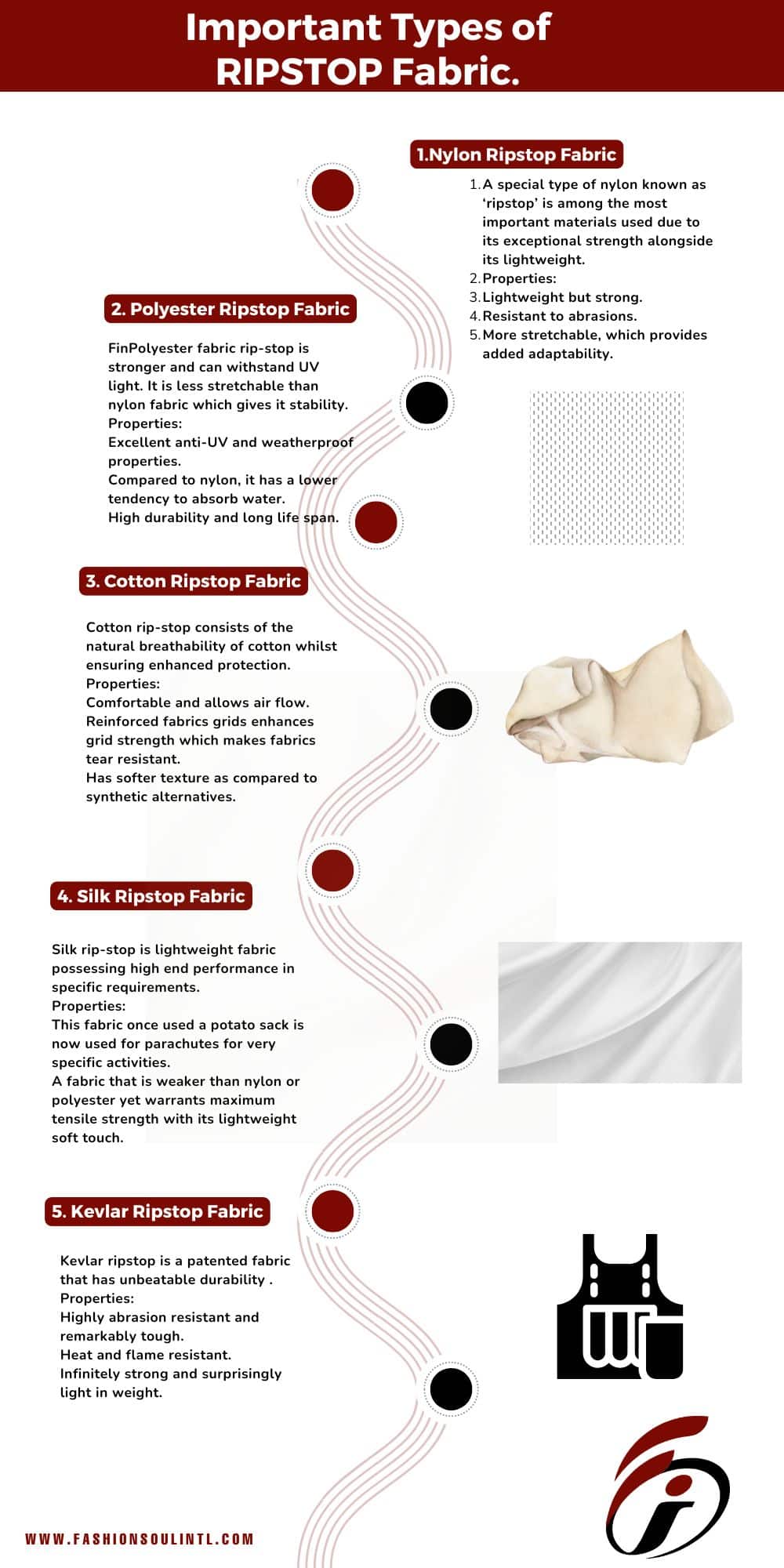

Types of Ripstop Fabric Based on Material

1. Nylon Ripstop Fabric

Ripstop, a special type of nylon, stands out as one of the most important materials due to its exceptional strength and lightweight properties. It is lightweight yet strong, resistant to abrasions, and highly stretchable, offering excellent adaptability. Manufacturers commonly use ripstop in backpacks, tents, sleeping bags, parachutes, kites, lightweight jackets, and sportswear.

2. Polyester Ripstop Fabric

Polyester ripstop fabric offers superior strength and resistance to UV light. Its lower stretchability compared to nylon provides greater stability. It resists water absorption more effectively than nylon, ensuring excellent durability and a long lifespan. Common uses for polyester ripstop include flags and banners, sailboat covers and canopies, military wear, and tarps.

3. Cotton Ripstop Fabric

Cotton ripstop combines the natural breathability of cotton with enhanced protection. It provides comfort and airflow, while its reinforced fabric grids improve strength and make it tear-resistant. Compared to synthetic alternatives, it offers a softer texture. Common uses include casual clothing like shirts and pants, lightweight upholstery, and construction workwear for mild conditions.

4. Silk Ripstop Fabric

Silk ripstop is a lightweight fabric that delivers high-end performance for specific requirements. Once used for potato sacks, it is now utilized for parachutes designed for specialized activities. While weaker than nylon or polyester, it offers maximum tensile strength combined with a soft, lightweight touch. Common uses include parachutes for specific purposes, specialty kites, and decorative items favored by the upper class.

5. Kevlar Ripstop Fabric

Kevlar ripstop offers unmatched durability with exceptional cut and heat resistance. Its patented design resists abrasions, withstands extreme heat and flames, and combines incredible strength with a lightweight structure. Manufacturers widely use it in tactical vests, other tactical gear, spacecraft deployment, and industrial protection equipment.

What is Gabardine Fabric?

Gabardine is a thick, twill-weaved fabric that features a diagonal rib on one side and a smooth surface on the other. Traditionally made of worsted wool, gabardine can be woven from cotton, polyester or some combination of these fabrics. The term “gabardine” originated with the late 19th-century Thomas Burberry, founder of the luxurious company Burberry, who marketed it as a waterproof material for outdoor use.

What is Batiste Fabric?

Batiste is a lightweight, plain weave fabric, often made from cotton, linen or even silk. It is unique in its lightness and comfort, which makes it ideal for summer wear and fine linens. Originally made of linen, Batiste was named after Jean-Baptiste Cambray, a 13th-century French weaver.

Advantages of Ripstop Fabric:

The Benefits Of Ripstop Fabric

Greater Strength: It has a high level of resistance to tearing and abrasion.

Sustainable Products: They can be used multiple times and in some cases, be recycled.

Tensile but Lightweight: They are strong but very easy to work with.

Water-Repellant: Good for outdoor and wet conditions.

Versatile: They come in various weaves and finishes which allow there application in many areas.

Conclusion

Ripstop fabric is an invention in the field of textile making. The fabric is strong and versatile. Its fiber characteristics which include tear resistance and lightweight performance, among others make this fabric ideal for diverse applications, ranging from recreational activities to the manufacturing industry. With knowledge of its composition and applications, one can appreciate the significance that this fabric brings to contemporary society.

FAQS

Manufacturers sought to develop a fabric that could maintain overall integrity even when torn or ripped; it is difficult to rip or tear ribstop fabric.

Nylon can also be colored in order to provide variations which makes it useful for a wider range of purposes.

Most ripstop fabrics come with coatings which are suitable for firefighting or operating in high extremes of heat.