Lycra fabric, a synthetic elastomeric fiber, offers exceptional elasticity. Chemist Joseph Shivers invented it in 1958 while at DuPont, and it quickly became a favorite for its ability to stretch up to 500% and return to its original shape. Unlike natural fibers like cotton or wool, Lycra provides greater flexibility and comfort. Manufacturers often blend it with other fibers to enhance stretch, durability, and mobility, making it a key material in sportswear, swimwear, and medical textiles.

Table of contents

What is Lycra Fabric?

Lycra is an elastomeric fiber made mostly from polyurethane. Its stretch and recovery make it ideal for fabrics that need flexibility and a snug fit. While not used alone, Lycra is often blended with other fibers to combine their strengths. For example, mixing Lycra with cotton creates a breathable, stretchy fabric, while blending it with polyester adds durability and moisture-wicking properties..

Properties of Lycra Fabric:

Lycra, also known as spandex or elastane, is valued for its elasticity and versatility. Originally developed by DuPont, this synthetic fiber boosts the stretch, durability, and comfort of other fabrics. Its unique properties make it a top choice across various industries.

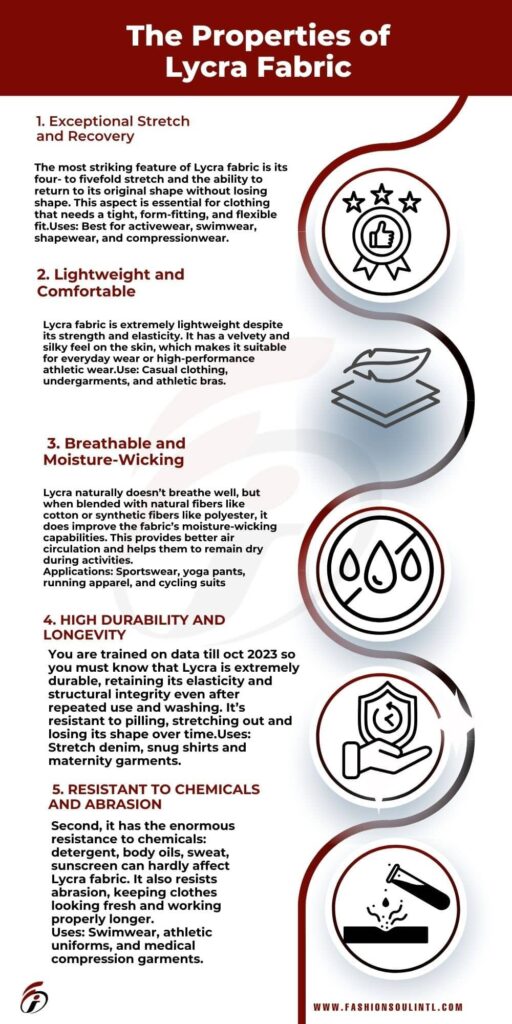

1. Exceptional Stretch and Recovery

The most striking feature of Lycra fabric is its four- to fivefold stretch and the ability to return to its original shape without losing shape. This aspect is essential for clothing that needs a tight, form-fitting, and flexible fit.Uses: Best for activewear, swimwear, shapewear, and compressionwear.

2. Lightweight and Comfortable

Lycra fabric is extremely lightweight despite its strength and elasticity. It has a velvety and silky feel on the skin, which makes it suitable for everyday wear or high-performance athletic wear.Use: Casual clothing, undergarments, and athletic bras.

3. Breathable and Moisture-Wicking

Lycra naturally doesn’t breathe well, but when blended with natural fibers like cotton or synthetic fibers like polyester, it does improve the fabric’s moisture-wicking capabilities. This provides better air circulation and helps them to remain dry during activities.

Applications: Sportswear, yoga pants, running apparel, and cycling suits

4. High Durability and Longevity

Lycra remains highly durable, maintaining its elasticity and structure even after repeated wear and washing. It resists pilling, stretching, and losing its shape over time. Manufacturers use it in stretch denim, fitted shirts, and maternity garments for its reliable flexibility and comfort.

5. Resistant to Chemicals and Abrasion

Second, it has the enormous resistance to chemicals: detergent, body oils, sweat, sunscreen can hardly affect Lycra fabric. It also resists abrasion, keeping clothes looking fresh and working properly longer.

Uses: Swimwear, athletic uniforms, and medical compression garments.

6. Quick-Drying lycra

Because it is synthetic, Lycra fabric dries more quickly than natural fibers such as cotton. This is particularly advantageous in activewear and swimwear, where rapid drying often represents a major benefit.

Uses: Swimwear, athletic shorts and activewear.

7. Wrinkle Resistance lycra

It does not wrinkle easily, so it keeps its crisp, smooth look all day. This characteristic is what makes it a go-to for travel-friendly apparel.

Uses: Officewear, travel, evening dresses.

8. Shape Retention lycra

One of Lycra’s stand out characteristics is exceptional shape retention. After stretching and pulling at it continuously, it goes back to its original form, making it best for clothes that require to hold their territorial army.

Examples of clothing items that fall under this category are leggings, bodycon dress, and body swimwear.

9. UV Resistance lycra

When it comes to Lycra cloth, some of the variants are made of UV-resistant material. It makes the fabric more efficient for outdoor activities.

Application: Outdoor sportswear, swimwear, and protective clothing.

10. Versatility lycra

Lycra offers great versatility and blends easily with natural and synthetic fibers like cotton, polyester, nylon, and wool. Mixing these fibers during yarn production enhances fabric performance, combining stretch with desirable properties such as softness and breathability.

How is Lycra Fabric Manufactured?

Lycra, also known as elastane or spandex, is a synthetic fiber renowned for its high elasticity and durability. Manufacturers produce Lycra through a series of steps, beginning with the chemical creation of polymers and culminating in the formation of thin, elastic fibers. Each step focuses on delivering fabric with key qualities such as stretchability, elasticity, and comfort. If you aren’t familiar, Lycra refers to a trademarked name for this ultra-thin, stretchable material.

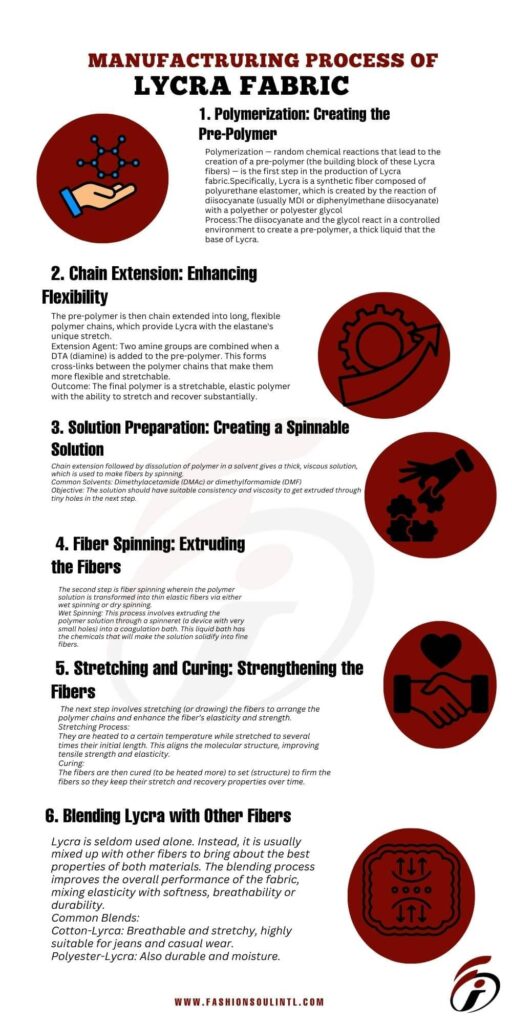

1. Polymerization: Creating the Pre-Polymer

Polymerization begins the production of Lycra fabric by creating a pre-polymer, the essential building block of Lycra fibers. Specifically, manufacturers synthesize Lycra as a synthetic fiber composed of a polyurethane elastomer. This elastomer forms when diisocyanate (typically MDI or diphenylmethane diisocyanate) reacts with a polyether or polyester glycol. In a controlled environment, the diisocyanate and glycol react to produce a thick liquid pre-polymer that serves as the foundation for Lycra.

2. Chain Extension: Enhancing Flexibility

The pre-polymer undergoes chain extension to form long, flexible polymer chains that give Lycra its distinctive stretch. When a diamine (DTA) is added, two amine groups combine, creating cross-links between the polymer chains. These cross-links enhance flexibility and stretchability. The process produces a stretchable, elastic polymer capable of substantial stretching and recovery.

3. Solution Preparation: Creating a Spinnable Solution

Chain extension, followed by dissolving the polymer in a solvent, creates a thick, viscous solution used for fiber production through spinning. Manufacturers typically use common solvents like dimethylacetamide (DMAc) or dimethylformamide (DMF) for this step. The process ensures the solution achieves the ideal consistency and viscosity for extrusion through tiny holes in the subsequent stage.

4. Fiber Spinning: Extruding the Fibers

In the fiber spinning step, manufacturers transform the polymer solution into thin elastic fibers using either wet spinning or dry spinning. During wet spinning, they extrude the polymer solution through a spinneret—a device with tiny holes—into a coagulation bath containing chemicals that solidify the solution into fine fibers. In dry spinning, they extrude the solution into a chamber where heated air evaporates the solvent, leaving behind solid fibers. This process produces long, continuous elastane fibers, commonly known as Lycra, ready for further processing.

5. Stretching and Curing: Strengthening the Fibers

In the next step, manufacturers stretch or draw the fibers to align the polymer chains and improve the fibers’ elasticity and strength. They heat the fibers to a specific temperature and stretch them to several times their original length, aligning the molecular structure to enhance tensile strength and elasticity. After stretching, they cure the fibers by heating them further to set their structure, ensuring the fibers retain their stretch and recovery properties over time.

6. Finishing: Preparing the Fibers for Use

The process of creating Lycra fibers continues with finishing steps to prepare them for blending with other fibers and eventual use in textiles. Manufacturers wash the fibers to remove residual chemicals or solvents. In some cases, they coat the fibers with a finish to improve compatibility with other fibers and ease handling during textile production. Finally, they wind the fibers onto spools or bobbins, ready for shipment to textile mills for blending and fabric production.

7. Blending Lycra with Other Fibers

Manufacturers rarely use Lycra on its own. Instead, they blend it with other fibers to combine the best properties of each material. This blending process enhances fabric performance, integrating elasticity with features like softness, breathability, or durability.

Common blends include:

- Cotton-Lycra: This breathable and stretchy combination is perfect for jeans and casual wear.

- Polyester-Lycra: This blend offers durability and moisture-wicking properties alongside added stretch.

- Nylon-Lycra: This pairing provides strength, smoothness, and stretch, making it an ideal choice for swimwear and lingerie.

8. Fabric Production: Weaving or Knitting

Lycra yarns are woven or knitted into fabric when blended with other fibers.

Weaving: Creates tightly woven textiles useful for denim and formal wear.

Knitting: Produces stretchable, pliable materials, bext for leggings, activewear and swimwear.

9. Dyeing and Finishing the Fabric

After weaving or knitting, manufacturers dye and finish the fabric. They use special dyes to color Lycra blends, ensuring the dyes bond firmly to the fibers without compromising elasticity. Finally, they treat the fabric with softeners, anti-static agents, and other finishes to improve texture, enhance aesthetics, and boost performance.

10. Quality Control and Inspection lycra

Manufacturers subject the fabric to strict quality control checks before sending it to garment producers. They test for elasticity to ensure the fabric meets required stretch and recovery properties. Strength tests assess its durability and tensile strength. During visual inspections, they look for defects such as uneven dyeing, snags, or weave irregularities.

Uses of Lycra Fabric

Lycra, also called LYCRA, spandex, or elastane, offers exceptional elasticity, making it highly valued for durability and comfort. However, manufacturers rarely use it alone; instead, they blend it with other fibers like cotton, polyester, or nylon to create textiles that combine stretch with additional attributes. Its versatility drives its widespread use in fashion, fitness, medical, and industrial textiles, among other sectors. Below, you’ll find detailed insights into the diverse applications of Lycra mule fabric.

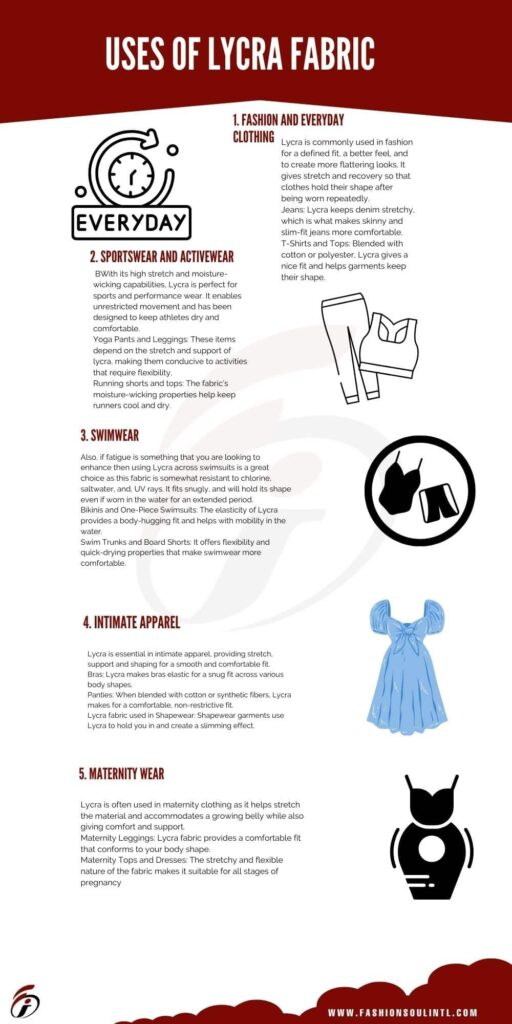

1. Fashion and Everyday Clothing of lycra

Lycra enhances fashion by providing a defined fit, superior comfort, and more flattering looks. It adds stretch and recovery, ensuring clothes maintain their shape even after repeated wear.

In jeans, Lycra keeps denim stretchy, making skinny and slim-fit styles more comfortable. For T-shirts and tops, manufacturers blend it with cotton or polyester to create a flattering fit and help garments retain their shape. Dresses often incorporate Lycra for a sleek, tailored fit in close-fitted, body-hugging designs. In skirts and trousers, it ensures a snug fit while maintaining a smooth silhouette for greater comfort. Additionally, undergarments like bras, panties, and shapewear rely on Lycra to deliver a supportive yet comfortable fit.

2. Sportswear and Activewear lycra

With its high stretch and moisture-wicking capabilities, Lycra is perfect for sports and performance wear. It enables unrestricted movement and has been designed to keep athletes dry and comfortable.

Yoga Pants and Leggings: These items depend on the stretch and support of lycra, making them conducive to activities that require flexibility.

Running shorts and tops: The fabric’s moisture-wicking properties help keep runners cool and dry.

Compression Wear: Lycra increases blood flow, oxygen supply and muscle support, preventing fatigue and increasing efficiency.

Cycling Apparel: The stretch and aerodynamic profile of lycra make it a popular choice for cycling shorts and jerseys.

Gym Wear: Lycra tank tops, sport bras and gym shorts allow flexibility and breathability for heavy workouts.

3. Swimwear lycra

Also, if fatigue is something that you are looking to enhance then using Lycra across swimsuits is a great choice as this fabric is somewhat resistant to chlorine, saltwater, and, UV rays. It fits snugly, and will hold its shape even if worn in the water for an extended period.

Bikinis and One-Piece Swimsuits: The elasticity of Lycra provides a body-hugging fit and helps with mobility in the water.

Swim Trunks and Board Shorts: It offers flexibility and quick-drying properties that make swimwear more comfortable.

4. Intimate Apparel lycra

Lycra is essential in intimate apparel, providing stretch, support and shaping for a smooth and comfortable fit.

Bras: Lycra makes bras elastic for a snug fit across various body shapes.

Panties: When blended with cotton or synthetic fibers, Lycra makes for a comfortable, non-restrictive fit.

Lycra fabric used in Shapewear: Shapewear garments use Lycra to hold you in and create a slimming effect.

Lingerie: Many delicate lingerie items include Lycra to provide a better fit and flexibility without sacrificing any style.

5. Medical and Healthcare Textiles

Due to the elastic and compressive nature of Lycra it’s a vital component in medical textiles, providing therapeutic and functional usability.

Compression Stockings: The lycra helps blood circulation, reduces swelling, and provides support in case of varicose veins.

Supports and Braces: It is used in knee braces, elbow supports and other orthopedic appliances to provide flexible support.

Post-Surgical Garments: Built from lycra, these garments are designed to provide gentle compression and support to patients post-surgery, aiding in the recovery process.

Medical Bandages: Lycra can be used to create bandages that wrap securely around wounds and injuries while still being flexible.

6. Industrial Applications of lycra

Aside from fashion and healthcare, Lycra is utilized in different industrial applications where flexibility and durability is required.

Automotive Seat Covers: Examples of lycra being formulated in conjunction with other fabrics are seat covers designed to hug the seat and allow for give.

Protective Gear: Lycra enhances the comfort and flexibility of protective gear worn in hazardous environments.

Elastic Cords and Bands: It is as one component of industrial elastic products from bungee cords to adjustable straps.

7. Home Textiles lycra

Lycra’s stretch and recovery benefits are also often used in home textiles to enhance the fit and durability of a variety of articles.

Fitted Bed Sheets: Lycra allows sheets to adapt easily to various sized mattresses, thereby ensuring that the sheets do not shoulder out.

Furniture Covers: Slipcovers for sofas and chairs are made with stretchable Lycra blends, providing a fit like a second skin.

Tight-Fitting Tablecloths: Lycra-means no more wrinkled tablecloths slipping around on your table.

8. Dance and Performance Wear

The stretchy fabric known was Lycra can also be popularly used for dancewear and dance performance costumes as it bends, stretches and moves with the body.

Leotards: Dancers and gymnasts often require lycra leotards, which provide flexibility and comfort.

Ballet Tights: The material gives a seamless, secure silhouette that elongates the dancer’s form and motion.

Stage Costumes: Lycra is frequently used in the costumes of theater and musical performances, enabling complex designs that move with the performer.

9. Maternity Wear lycra

Lycra is often used in maternity clothing as it helps stretch the material and accommodates a growing belly while also giving comfort and support.

Maternity Leggings: Lycra fabric provides a comfortable fit that conforms to your body shape.

Maternity Tops and Dresses: The stretchy and flexible nature of the fabric makes it suitable for all stages of pregnancy

10. Footwear and Accessories

When it comes to footwear and accessories, it’s also used in its production when flexibility and a snug fit are key.

Sneakers & Athletic Shoes: Lycra controls the fit of uppers.

Gloves: Lycra stretch gloves provide a snug fit and enhanced dexterity.

Hats and caps: Blended with lycra for a snug fit plus comfort.

Types of Lycra Fabric

Lycra fabric (or elastane / spandex) is a popular synthetic fibre with excellent stretch and recovery properties. Although Lycra is a specific brand of spandex or elastane, and thus alone is trademarked by DuPont (now part of The LYCRA Company), it is held commonly, referring to spandex or elastane in general.] Some common types of Lycra fabric help satisfy particular performance, aesthetic, and comfort needs. To enhance specific qualities, these distinctions are made by mixing Lycra with varying fibers or altering its chemical structure.

Here’s an in-depth overview of the different types of Lycra fabric, along with their uses:

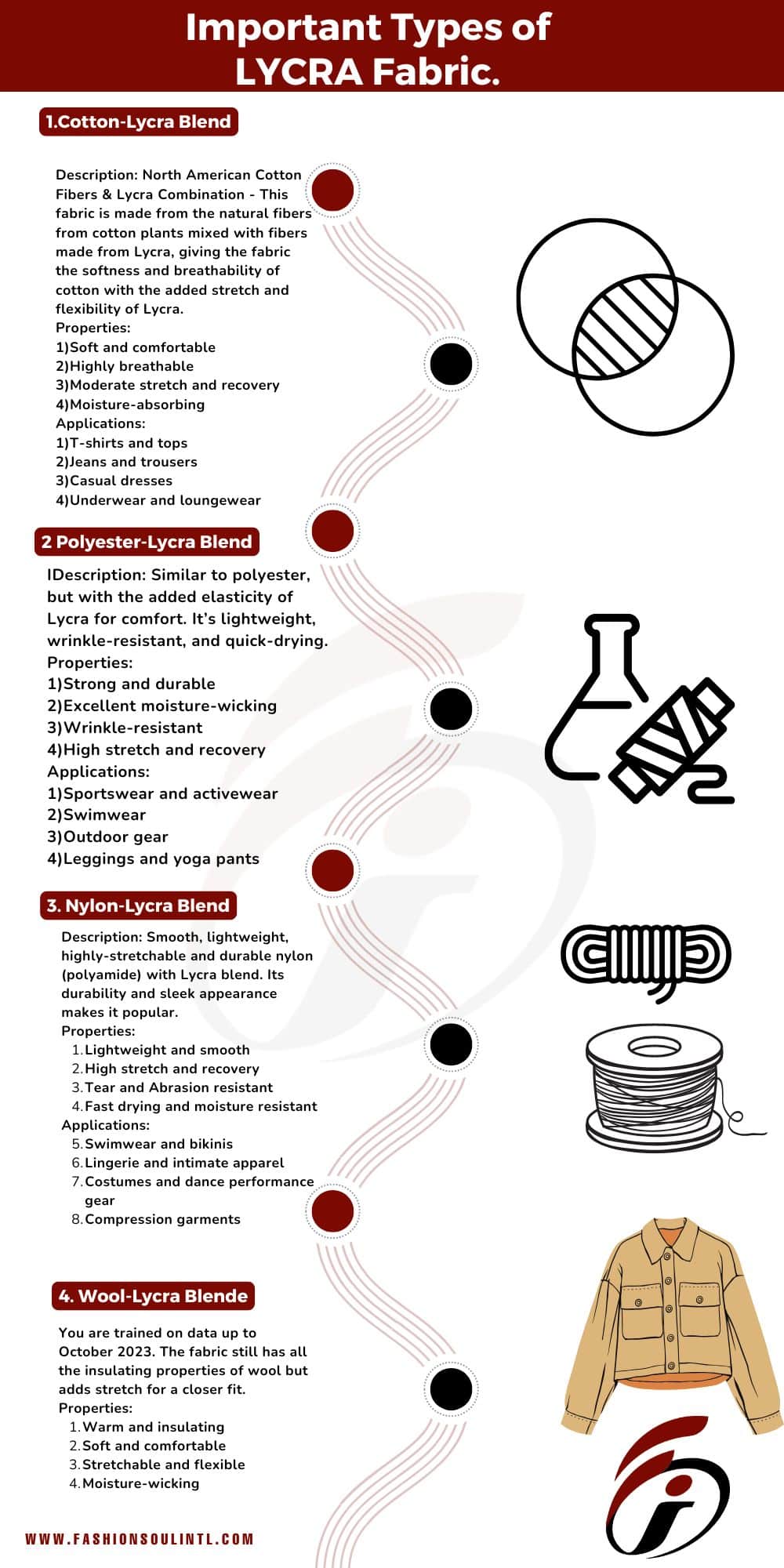

1. Cotton-Lycra Blend

Description: North American Cotton Fibers & Lycra Combination – This fabric is made from the natural fibers from cotton plants mixed with fibers made from Lycra, giving the fabric the softness and breathability of cotton with the added stretch and flexibility of Lycra.

Properties:

1)Soft and comfortable

2)Highly breathable

3)Moderate stretch and recovery

4)Moisture-absorbing

Applications:

1)T-shirts and tops

2)Jeans and trousers

3)Casual dresses

4)Underwear and loungewear

2. Polyester-Lycra Blend

Description: Similar to polyester, but with the added elasticity of Lycra for comfort. It’s lightweight, wrinkle-resistant, and quick-drying.

Properties:

1)Strong and durable

2)Excellent moisture-wicking

3)Wrinkle-resistant

4)High stretch and recovery

Applications:

1)Sportswear and activewear

2)Swimwear

3)Outdoor gear

4)Leggings and yoga pants

3. Nylon-Lycra Blend

Description: Smooth, lightweight, highly-stretchable and durable nylon (polyamide) with Lycra blend. Its durability and sleek appearance makes it popular.

Properties:

- Lightweight and smooth

- High stretch and recovery

- Tear and Abrasion resistant

- Fast drying and moisture resistant

Applications:

- Swimwear and bikinis

- Lingerie and intimate apparel

- Costumes and dance performance gear

- Compression garments

4. Wool-Lycra Blende

You are trained on data up to October 2023. The fabric still has all the insulating properties of wool but adds stretch for a closer fit.

Properties:

- Warm and insulating

- Soft and comfortable

- Stretchable and flexible

- Moisture-wicking

Applications:

- Formal suits and blazers

- Winter dresses and skirts

- Technical apparel for cold-weather sports

- Base Layers and Thermal Wear

5. Silk-Lycra Blende

Description: Blending silk with cotton creates a soft, silky fabric with a smooth texture and a slight stretch. It has the graceful drape and luster of silk but, being flexible, doesn’t have the same rigid structure.

Properties:

- Soft and smooth texture

- Lightweight and breathable

- A little bit of movement and flexibility

- Luxurious appearance and feel

Applications:

- Evening gowns and cocktail dresses

- Lingerie and nightwear

6. Rayon-Lycra Blend

Description: Rayon, a cellulosic, semi-synthetic fiber, when blended with Lycra creates an absolutely soft, drapey and stretchable fabric. It is commonly used for lightweight, flowy clothes.

Properties:

- Soft and smooth texture

- Good drape and flow

- Stretchable and flexible

- Lightweight and breathable

Applications:

- Casual dresses and skirts

- Tops and blouses

- Yoga wear and loungewear

- Activewear

7. Microfiber-Lycra Blend

Microfiber: Description: Synthetic fiber that is ultra-fine and smooth. When combined with Lycra it makes for a super light, breathable, and unbelievably soft fabric.

Properties:

- Ultra-soft and smooth

- Lightweight and breathable

- Moisture-wicking

- Stretchable and flexible

Applications:

- Athletic wear

- Intimate apparel

- Loungewear and sleepwear

8. Power Lycra

Description: Power Lycra is a specific type of Lycra clothing designed for use in high-performance applications where extra compression and support is needed.

Properties:

- High compression and support

- Strong and durable

- Great stretch and recovery

- Moisture-wicking

Applications:

- Compression garments

- Shapewear

- Sports bra and athletic support

- Medical braces and wraps.

Environmental Impact of Lycra Fabric

Lycra is also special in that it comes with its share of eco-problems; Being a synthetic fibre, it is made from petroleum based resources which means it adds to carbon emissions. Washing Lycra can also release microfibers, which do not biodegrade, and may enter waterways.

Nonetheless, the textile industry is moving in the direction of sustainability, with eco-friendly options and recycling systems for Lycra clothing in progress. Other brands are researching bio-based elastane fibers, which reduce the environmental footprint yet still deliver on performance.

Caring for Lycra Fabric:

Taking good care of Lycra can help improve the lifespan of these garments, as well as their performance. Here are some tips:

If you do wash them, wash in cold water so you don’t ruin the elastic fibers.

Skip fabric softeners because they can break down the elasticity.

Whenever possible, air dry instead of using a dryer to keep them in good shape.

Hang to dry. Fold instead of hanging to avoid stretching.

FAQS

Lycra material is composed of urethane, a type of artificial polymer recognized for its outstanding flexibility.

Lycra is a main name for spandex fabric, which is a synthetic elastic fabric. The terms “Lycra”, “spandex”, and “elastane” all are the different name of one fabirc.

Yes, and Lycra is usually blended with breathable fibers, so it’s also used for activewear and sportswear.

Conclusion

Lycra Material Is A Change Agitator In The Textiles Framework Offering Matchless Adaptability, Solace, And Strength Its versatility makes it a useful material for a wide variety of applications, from fashion to fitness and more. With the industry’s shift to sustainability, pay attention to continued evolution from Lycra in delivering better solutions for consumers as well as solutions to preserve the environment.

What is poplin Fabric?

Poplin, also known as tabinet, features a simple weave and a satiny texture that gives it a sleek, smooth feel. While manufacturers originally used cotton to produce poplin, they now incorporate polyester, silk, or synthetic fibers to enhance its strength and flexibility. The fabric gets its name from the French word papeline and traces its origins to Avignon, where craftsmen in the 15th century created it for papal uniforms. Today, people recognize poplin for its velvety softness, smooth sheen, and impressive strength-to-weight ratio, making it a popular choice for both fashion and functional applications.