Introduction

There is another fabric that is versatile and most commonly used in the textile industry today and it is called Rayon. Rayon is well-known by its smooth surface, softness, and the possibility of imitating various other materials, which is why it may be found in any wardrobe, home furnishings, or even medical use. Even though it is popular, there has been a debate that has been going on; is rayon a synthetic fiber? This question is not as simple as it can be thought.

This misunderstanding owes much to the method of production of rayon and what is used to make it. Rayon starts as something real unlike polyester or nylon which are completely synthetic. Its raw material cellulose, which is a constituent in wood pulp, gives it a feel and attributes of a natural fiber. It is, however, partly synthetic since it goes through complicated chemical processes. So, let us make this simple.

Is Rayon a synthetic Fiber? True Classification explained

What is the short answer? Rayon is semi-synthetic in nature. It is a natural cellulose mostly of wood pulp, chemically treated and then processed into usable fabric. This special mix places it in an intermediate between natural fibers such as cotton and completely synthetic such as polyester.

Is Rayon a Synthetic Fiber? Understanding the True Classification

To give an example, consider the following:

- Natural fibers (cotton, wool etc.) are the ones directly obtained by plants or animals and require little processing.

- Man made fibers (e.g. polyester, nylon) are pure petrochemicals synthesized by reaction into polymer.

- Rayon in its turn is originated with wood pulp (natural) being changed chemically, therefore, not a completely natural fabric, also not fully synthetic.

Due to this reason rayon is usually referred to as regenerated cellulose fiber and is therefore one of the very first man made fibers ever made.

What is The Processing of Rayon? What is the Viscose Process?

In order to comprehend why rayon is semi-synthetic we have to be familiar with the way how it is processed. Viscose process is the most usual fabricating process and it includes creating pulped wood into fiber by a voyage of chemicals.

This is how it goes:

- Sodium hydroxide (NaOH) is used to dissolve wood pulp.

- The cellulose produced is then converted into alkali cellulose that is treated with carbon disulfide (CS 2 ) to obtain cellulose xanthate.

- This mixture is once again dissolved in sodium hydroxide to form a viscous solution- hence the name viscose.

- The solution passes through spinnerets into an acid bath to get it solidified into fibers.

It is because in this process natural cellulose is converted to a new fiber structure, rayon is sometimes divided into regenerated cellulose. It is no longer what it once was but at the same time, it is not completely fake.

Types of Rayon: Variants and Their Unique Qualities

Viscose Rayon

This is the most widespread of the rayons and it is a replica of the traditional viscose process. It is lightweight, breathable and flows well and it has been popular in fashion. Nevertheless, it is also not as durable and environment-neutral, as it uses chemicals.

Modal Rayon

Modal is a variety of rayon which is made of beech trees. It is produced by a modified viscose process and is therefore more resistant to shrinkage as well as stronger. Modal is popular to be applied in underwear and sportswear, bedsheets because the material feels silky and is more durable.

Lyocell (Tencel)

The rayon alternative is the most nature friendly variety, which goes by the label Lyocell or Tencel brand name. It involves closed-loop system where water and solvents are recycled. It is still chemically processed but it is much more environmentally friendly than other types of rayon and it has become popular in the ethical fashion industry.

All the types have their own distinctive qualities, yet they are all made out of cellulose, and are somehow chemically converted in some way.

Properties of Rayon: Benefits and Drawbacks

There are some wonderful qualities of rayon:

- Breathability: Rayon is breathable and it keeps the body cool.

- Absorbency: It is capable of absorbing moisture; hence it fits in humid climate.

- Drape: The cloth can be folded beautifully and looks like silk or cotton.

Though the above are very strong, there are weaknesses in rayon:

- Durability: Whilst it is weak when wet, and can be torn easier than cotton.

- Shrinkage: When it is not properly washed it shrinks up to a considerable extent.

- Environmental issues: The production process uses chemicals intensively and this problem involves an unhealthy waste management.

Due to this kind of balanced strengths and weakness, rayon is mostly mixed with some other fibers to perform higher.

Rayon and Synthetic Fibers: A Non-Standard Man Made Material

Rayon is chemically processed but unlike synthetic fibers such as polyester, nylon and acrylic, has different properties.

Major differences are:

- Feel: Rayon does not feel like rayon as much as cotton or silk and synthetics may feel plastic.

- Breathability: Rayon is more fermentable and can thus be used during the summer.

- Eco-content: Rayon uses natural materials as a basis: synthetics use petroleum.

The differences are evident on why the question should not be Is rayon a synthetic fiber? It has more of a natural fibers performance, although it is chemically treated.

Rayon Vs Natural Fibers: Closing the Gap

Rayon is dubbed as the electric silk due to its softness and opulence looking feel. However how do the synthetic fibers compare to natural fibers such as cotton, linen or silk?

Similarities:

- Tenderness and comfort

- Breathability

- Moisture absorption

Differences:

- Origin: Chemical The natural fibers do not need much chemical processing.

- Durability: Natural fibers tend to be stronger particularly when they are wet.

- Sustainability: Depending on their farming or processing, natural fibers may be more sustainable.

Although the rayon looks like the original, the chemical treatment somewhat categorizes it as another category.

Environmental Impact of Rayon: The Hidden Cost

Big-time concern among environmentalists is the production procedure of rayon. The effect of this comes not only in terms of using natural materials as it is made of wood pulp.

Key Issues:

- Deforestation: Forests commonly comprise of endangered ecosystems and this is cut down due to the large-scale production of rayon.

- Chemical Waste: Carbon disulfide and other hazardous chemicals are used and this is a major health hazard to the employees and the adjacent water bodies.

- Air Pollution: Industries which fail to address the issue of emissions cause environmental problem through air pollution.

Nevertheless, not every rayon is dangerous. Bamboo rayon (as produced responsibly) and lyocell have greater sustainable options. These are eco-friendly solvent and renewable sources.

Common Uses of Rayon in Everyday Life

The reason Rayon has been considered one of the most viable options to use by so many industries is due to its diversified nature. It is cheaper and comfortable and thus is applied in many products.

Fashion & Apparel:

- Dresses, blouses and scarves of the summer kind

- Jacket and suit linings

Home Textiles:

- Pillow cases and bed sheets

- Upholstery and curtains

Medical & Industrial Uses:

- Surgical gowns Disposable surgical gowns are made of a thin film of polyethylene, polypropylene, or polyurethane.

- Hygienic products such as wipes and swabs

Due to its soft nature and relative cheapness, rayon may substitute more expensive natural fibers, in these uses.

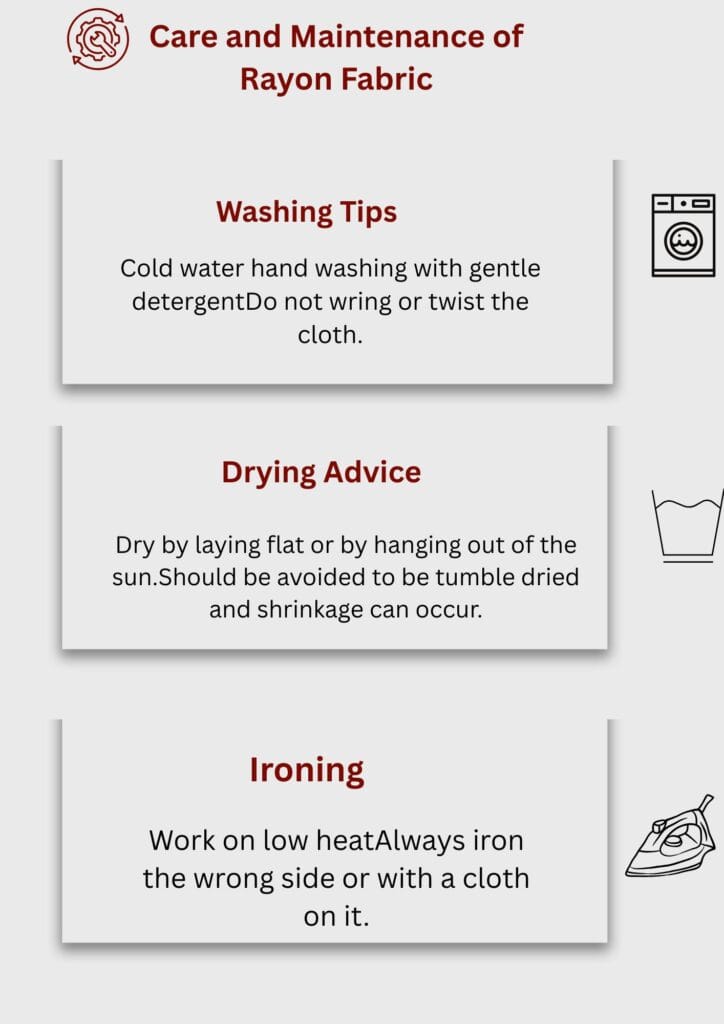

Care and Maintenance of Rayon Fabric

Rayon has to be handled with special care in that it has to be maintained in terms of its look and feel. It is weaker than cotton or polyester, particularly when it is wet.

Washing Tips:

- Cold water hand washing with gentle detergent.

- Do not wring or twist the cloth.

Drying Advice:

- Dry by laying flat or by hanging out of the sun.

- Should be avoided to be tumble dried and shrinkage can occur.

Ironing:

- Work on low heat.

- Always iron the wrong side or with a cloth on it.

Rayon clothes sustain durability provided that they are properly cared.

Common Misconceptions About Rayon

Rayon Is Natural – This Is Not So True

Although rayon is derived out of natural cellulose, the chemical process carried with it does not make it that genuine. It is a synthetic fabric that weaves out of nature, and it takes place on the hybrid scale.

Rayon Is Friendly to the Environment- Only Sometimes

Most people think that rayon is a sustainable fiber since it comes out of the plant. However, conventional manufacturing of rayon may result in serious environmental damage. Newer processes such as Lyocell or certified eco-bamboo rayon are the only ones that could be characterized as eco-friendly.

The concept of these myths when understood by the consumer assists them make an informed decision in terms of purchase.

Future of Rayon & Sustainable Alternatives

Rayon manufacturing is going to be a result of innovation. New technologies will help in decreasing the chemical usage, solvent recycling, as well as encouraging better forestry.

There are Positive Advances In:

- Recycled water and chemicals, in a closed-loop system.

- Captured sustainable resources of wood to avoid deforestation.

- Micro plastic pollution reducing biodegradable blends.

Brands Leading the Way:

- Tencel is applied in environmentally-friendly collections by Patagonia and Levi.

- H&M and Zara make use of Modal and Lyocell in their conscious lines.

The trend towards sustainability is on the increase and the future of rayon can be determined by the degree to which the industry is able to adjust.

Conclusion

The confusion is finally resolved- rayon is semi synthetic fiber. It is created out of natural cellulose, yet undergoes a chemical process of manufacturing a useable fabric. This positions is as unique in itself between natural and synthetic fibers.

It becomes easy to eliminate the myths when you first understand how it is made, the rays properties and its origin, as consumers are able to make the correct decisions. Even though the conventional rayon is environmentally undesirable, recent types can provide a combination of sustainable options, touching on comfort, functionality, and responsibility.