Introduction

Viscose or rayon is taking the fashion world by storm, gaining popularity as a semi-synthetic fiber. Viscose is produced through the chemical treatment of wood pulp, which extracts cellulose, creating a soft and adaptable thread. It is often considered a blend of cotton and silk due to its texture and gloss respectively and is marketed as a ‘more natural’ substitute to synthetic fibers.is viscose sustainable

Is Viscose Sustainable? Why adopt such a sustainable approach to sourcing fabric and materials risks sustainability for the frame of supply chain transparency and the abiding environmental regulatory practices executed. Many consumers view Viscose as eco-friendly thanks to its plant based origins however, its real impact is more complicated than that..

Viscose Rayon Creation

The creation of viscose starts with the dissolution of wood pulp. Trees like beech, pine, or eucalyptus are made to bamboo to the branches shredded into tiny slivers while immersed in a chemical slurry. Once laced into this batter, they extract ‘spinnerets,’ or small containers filled with gel-like liquid through which tiny cotton threads are spun.

What comes down from the factory is a fabric mixture that is lightweight yet steam permeable. While not entirely synthetic, viscose possesses a unique divergence when compared to cotton and polyester mix.

Why Is It Popular in Fashion?

At a low cost, viscose gives off a silky appearance. It is breathable like cotton and drapes nicely, so it is easy to wear for dresses, blouses, and even dress linings. That is the reason why many manufacturers promote it as a premium substitute for synthetic fibers.

Brands enjoy selling garments made from viscose because it is relatively easy to dye. This allows designers versatility and makes it easier for them to be creative. The comfort viscose offers is one of the contributing factors for its use in both fast fashion and high-end clothing.

How is Viscose Made? (The Production Process Behind Viscose Sustainability)

People concerned about the sustainability of viscose often wonder, is viscose eco-friendly? Such questions arise because even though viscose has its origins in wood pulp, the process uses a number of harmful chemicals.

The Chemical Process

Sodium Hydroxide and carbon disulfide are some of the toxic chemicals used in Viscose production. They are used to dissolve wood pulp which can then be reformed into threads.

These chemicals are not benign, especially carbon disulfide, which is detrimental to the workforce and the planet as a whole. People who work in places without proper regulations are the ones who suffer the most, as this waste irresponsibly ends up in nature. Long term exposure to these chemicals can result in severe mental and reproductive issues.

Comparison with Other Semi-Synthetic Fabrics

Modal and lyocell as well as viscose are considered semi-synthetic because they share the fibers of plants. Unlike the other modal, it has a better recovery system which makes its production more environmentally friendly since it is produced with a modified viscose process. TENCEL™ does have an advantage as it operates within a closed-loop system that reuses 99% of solvents, making it more sustainable and environmentally friendly.

Environmental Concerns in Manufacturing

The method of making viscose contributes to deforestation and old growth forests have been cut down to plant viscose and other plantations which harms endangered habitats . In addition to this, many factories which are poorly controlled dump wastewater and chemicals directly into rivers which harms the ecosystems and communities along with biodiversity.

When looking into whether viscose is sustainable or not, it is evident to see the reason behind it heavily depends on how responsibly the viscose is produced.

Is Viscose Sustainable? (Unpacking the Debate)

Understanding whether viscose is sustainable requires looking into both its advantages and disadvantages. As with many types of textiles, the answer is somewhat ambiguous.

Pros of Viscose Sustainability

- Biodegradable: Viscose breaks down naturally while polyester accumulates in a landfill.

- Renewable Sources: As long as trees are responsibly managed and harvested, they can be renewed.

- Low Energy Use: The energy required for processing the fibers of viscose is lower than for synthetic fabrics.

These characteristics make viscose appear environmentally friendly. However, there are many other considerations that impact its sustainability.

Cons of Viscose Sustainability

- Deforestation: Leads to habitat destruction, primarily in Indonesia and Brazil due to unsustainable harvesting practices.

- Toxic Chemicals: The chemical Carbon disulfide causes health problems for people working with the substance and contaminates water bodies.

- Water Consumption: The manufacturing process of viscose utilizes large amounts of water which impacts local water resources.

Therefore, viscose can only be classified as sustainable if there are strict controls for sourcing and processing.

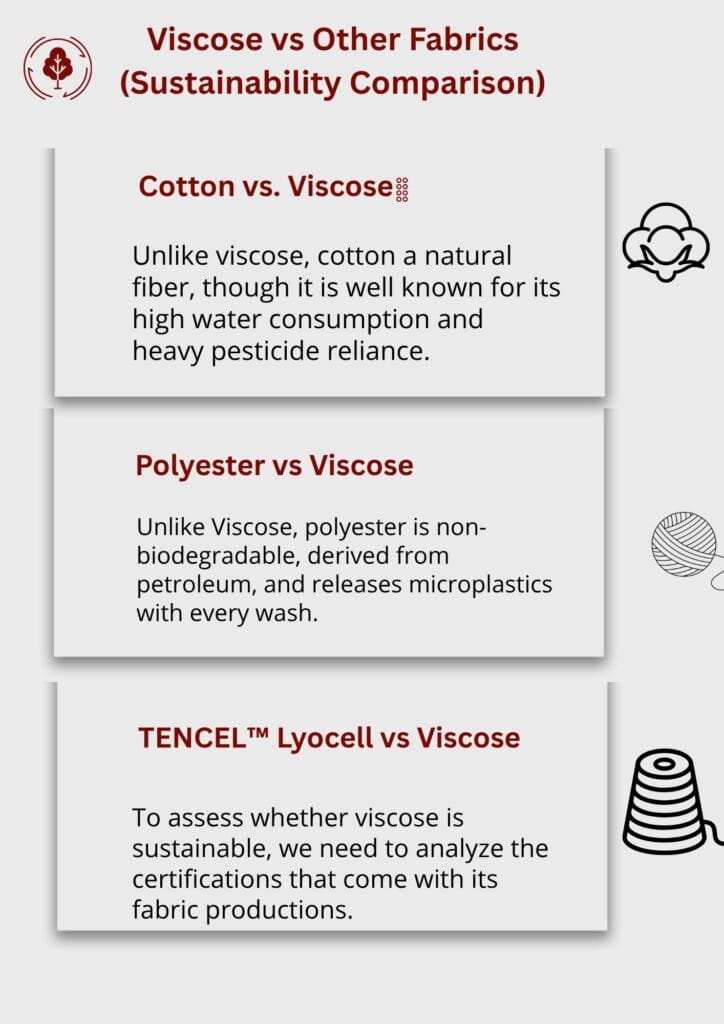

Viscose vs Other Fabrics (Sustainability Comparison)

In order to answer the question, is viscose sustainable, we should analyze relative to other common fabrics.

Cotton vs. Viscose⠀

Unlike viscose, cotton a natural fiber, though it is well known for its high water consumption and heavy pesticide reliance. Viscose has a competitive advantage since it requires less land, and can be grown more quickly . Despite this, Cotton’s organic and regenerative farming practices of recent years have enhanced its sustainability.

Polyester vs Viscose

Unlike Viscose, polyester is non-biodegradable, derived from petroleum, and releases microplastics with every wash. On the other hand, viscose decomposes naturally without harming the environment, making it superior to polyester in waste reduction.

TENCEL™ Lyocell vs Viscose

Tencel™ sources its wood pulp from FSC certified forests, making its production more sustainable than other semi-synthetic fabrics. Because of this, Tencel™ Lyocell’s closed loop process renders it the most sustainable Tencel™ is produced with a significantly lowered environmental impact than viscose and it utilizes a lot less resources.

Viscose Sustainability Certifications

To assess whether viscose is sustainable, we need to analyze the certifications that come with its fabric productions. These labels assist consumers in recognizing responsible products.

FSC (Forest Stewardship Council)

The FSC certifies that the wood used comes from responsibly managed forests. Products with this label help prevent illegal logging and deforestation.

OEKO-TEX®

This label certifies that the final product of fabrication does not retain harmful chemicals, thus offering protection for the user and the ecosystem.

EU Ecolabel

It awarded the label to products that had an evaluated and lowered the environmental footprint. EU Ecolabel has reviewed the life cycle of a textile from raw material acquisition to disposal.

CanopyStyle Initiative

This initiative partners with brands to stop using forests at risk of deforestation for producing viscose. More than 500 brands have adopted its principles, leading to substantial changes in the industry.

Brands Using Sustainable Viscose

These brands respond to market pressure and ecological need by changing their use of viscose.

Brands Using EcoVero™ (Lenzing)

Lenzing’s EcoVero™ viscose utilizes FSC certified wood and emits 50% less greenhouse gas, making it a branded EcoVero™ viscose. Brands such as Armedangels, People Tree, and Thought Clothing incorporate EcoVero™ into their collections.

TENCEL™ Lyocell

Patagonia, Eileen Fisher, and Reformation are ethical brands committed to sourcing TENCEL™. These brands are known for their transparency with consumers and stick to closed-loop, low-impact production models.

Fast Fashion Brands Improving Viscose Sourcing

Even these brands are making some positive strides. Responsible viscose is now included in the assortments of H&M Conscious and Zara’s Join Life collection. These moves, however, are criticized for lacking systemic changes.

How to Identify & Buy Sustainable Viscose

Most consumers unwittingly choose low-impact products and services simply because they are available. Certified brands are usually the easiest to determine when your goal is to make a good decision.

FSC or TENCEL™ Certifications

Do not forget to look at the label. Certifications by FSC and TENCEL™ Viscose factories gives confidence that the viscose to be used is properly obtained from the forest preserves and other important ecosystems.

Untraceable Sources of Viscose

A firm that does not bother about the supply chain of its viscose stands an increased chance of dealing with un-sustainably harvested materials or pollution. Lack of disclosure has never been and will never be ideal.

Open Supply Chains

Companies that have open supply chains tend to act more responsibly. Look for sustainability reports as well as second party audits.

Will Viscose Be More Eco-Friendly?

The question of sustainability is ultimately in the hands of the makers of the fabric and how much they are willing to spend on research and development. The introduction of new technologies could very well bring an answer – yes.

Methods for Emission Reduction

Innovation in closed-loop production, such as the TENCEL™ process, could yield a far less harmful method for producing viscose. Systems that are closed to the environment drastically reduce emissions and pollutants.

Other Fabrics

The use of wood fiber can be replaced by orange fiber, viscose, or fabric made from agricultural waste. These not only replace raw materials but also help in waste management.

The Change Resulting from Consumer Demand

With the increasing adopters of “is viscose sustainable,” companies try to innovate to meet their demands. Today, Responsible sourcing is becoming an expected standard for many markets.

Conclusion

The answer to the question posed is not entirely clear given that viscose can be eco-friendly only if made under tight environmental controls.

Viscose is deforesting and polluting the eco-system. viscose production is far from eco-friendly due to the deforestation and pollution it causes. Some alternatives do exist, for example certified EcoVero or Tencel.