Bamboo fabric is turning into more and more well-appreciated because of its many uses and environmentally beneficial features.

What distinguishes this novel material in today’s sustainable fashion world is its unique creation process. Designers specially craft it by combining eco-friendly materials with innovative techniques. We will have a look at the manufacturing approach, salient traits, and myriad packages of bamboo fabric in this vast academic.

Table of contents

What is Bamboo Fabric?

Manufacturers create bamboo fabric by processing bamboo pulp. Manufacturers weave this precious fibre in a number of forms, from hard linen to soft bamboo viscose. In addition, because bamboo cloth is biodegradable, it’s a sustainable option. This in turn means that consumers as well as businesses have it at their disposal for minimizing their carbon footprint efficiently.

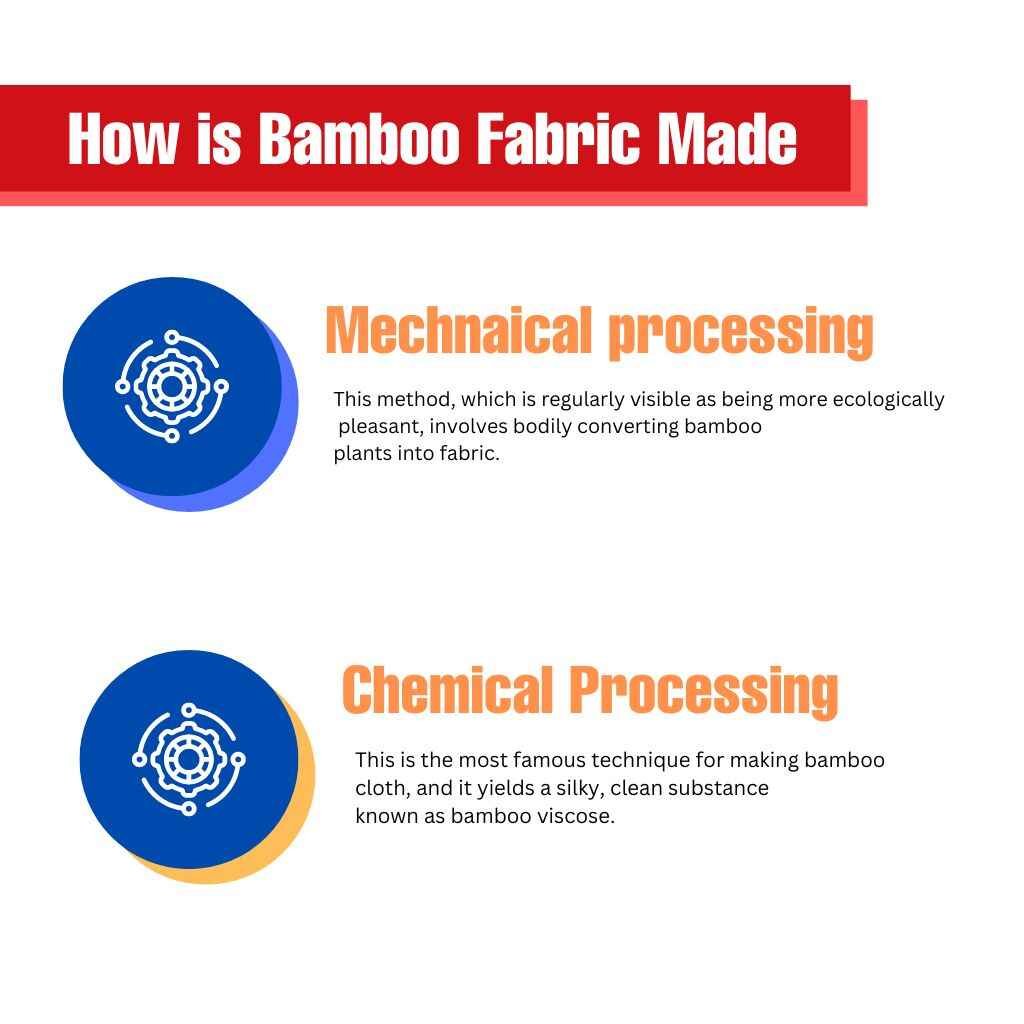

How is Bamboo Fabric Made?

Bamboo material comes into use in different ways, depending on the material they are manufacturing and how they make it. Basically, they operate under two approaches, chemical and mechanical processing. Each technique employs its own process and produces its own fabric.

1. Mechanical Processing (Bamboo Linen)

This method, which is regularly visible as being more ecologically pleasant, involves bodily converting bamboo plants into fabric. The essential movements are as follows:

Harvesting Bamboo

When bamboo plants grow large, typically after 3 to 5 years, harvesters cut them down. They carefully remove the shoots without damaging the root system, allowing the plants to regrow.

Crushing Bamboo Stalks

Workers crush and break down the harvested bamboo into a pulp. This process usually involves using machinery to physically crush the bamboo into fibers.

Retting and Scutching

Retting the bamboo pulp is soaking the fibers in water to lead them to soften. After that, workers use a procedure called scutching to process the softened pulp and separate the individual fibers.

Spinning Fibers into Yarn

Manufacturers create yarn from individual bamboo fibers. They then weave it into linen, a fabric with a texture similar to traditional linen.

Finishing the Fabric

To get it ready for purchaser usage, the cloth goes through completing steps inclusive of washing, loss of life, and cutting after weaving.

2. Chemical Processing (Bamboo Viscose/Rayon)

This is the most famous technique for making bamboo cloth, and it yields a silky, clean substance known as bamboo viscose. The movements consist of:

Extraction of Bamboo Cellulose

To dissolve the bamboo cellulose into a viscous liquid, manufacturers immerse the broken-down bamboo stalks in a chemical solution, typically sodium hydroxide.

Filtering and Solidifying

Manufacturers strain the gummy mixture through filters to get rid of the dirt, and spinnerets spin out the cellulose into fibres.

Spinning and Weaving

By knitting or spinning these fibres, they knit or spin bamboo viscose fabric. The resulting fabric is breathable, silky and extremely soft.

Closed-Loop Systems

To reduce their effect on the environment, many modern-day producers recycle the chemical compounds used inside the manufacturing of bamboo fiber with the aid of the usage of closed-loop systems at some point at the chemical processing level.

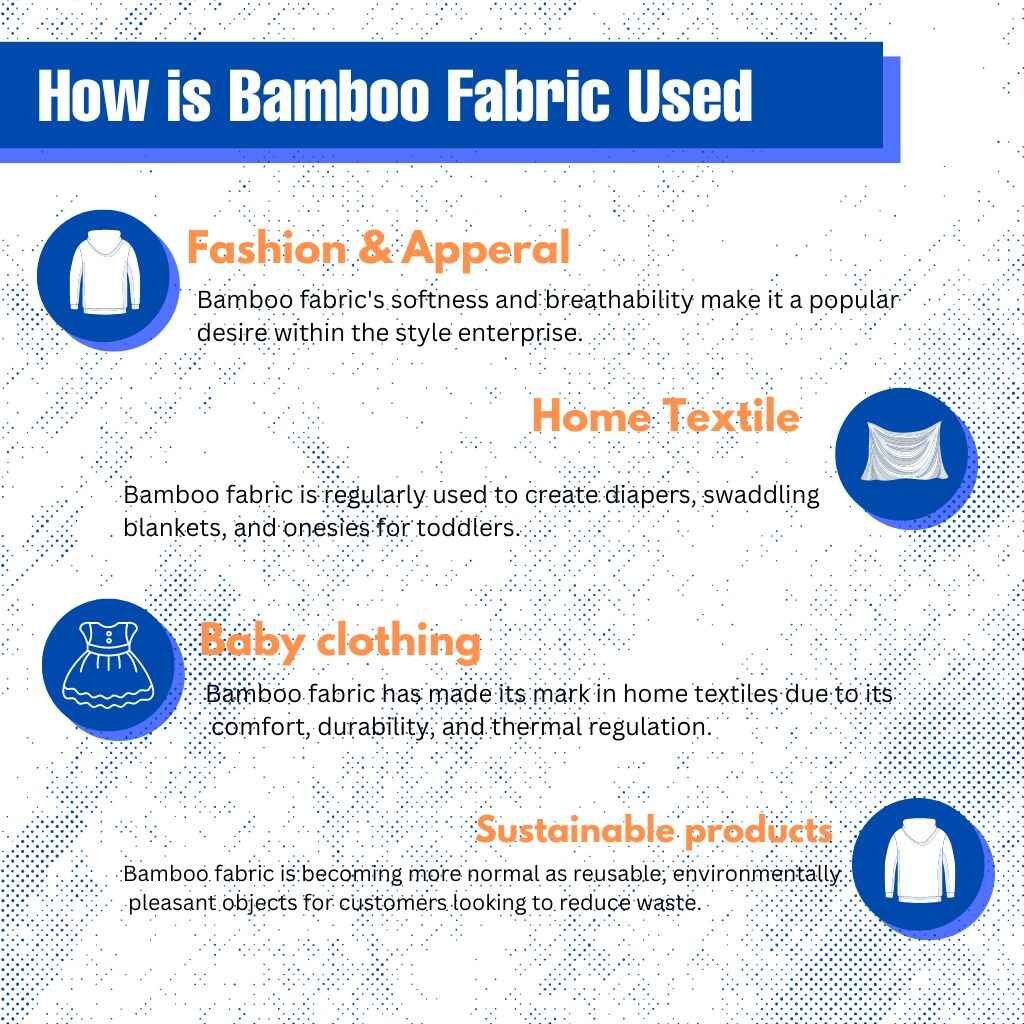

How is Bamboo Fabric Used?

Bamboo material is extraordinarily adaptable and utilized in plenty of one-of-a-type sectors for lots of purposes. People use it for many specific functions because of its softness, durability, and environmental friendliness.

Fashion and Apparel

Bamboo fabric’s softness and breathability make it a popular desire within the style enterprise. Among the most properly-preferred products constructed from bamboo material are:

Clothing

Manufacturers craft many items, such as dresses, underwear, socks, and t-shirts, from bamboo material. Its moisture-wicking and hypoallergenic characteristics make it ideal for clothing that is near the skin.

Activewear

Bamboo fabric is desired for wearing yoga garb due to its potential to wick away moisture and possess antimicrobial characteristics. It maintains athletes dry and cool all through strenuous exercising.

Sustainable Fashion

Sustainable sustainability has drawn the attention of moral style manufacturers to bamboo’s green characteristics. Bamboo cloth is increasingly more often used in environmentally conscious designs.

Home Textiles

Bamboo fabric has made its mark in home textiles due to its comfort, durability, and thermal regulation. Common uses include:

Bedding

Those with allergies or sensitive skin especially favor bamboo bedding for its warm temperature and ability to regulate frame temperature. Bamboo blankets, pillows, and mattress linens are prized for this quality.

Towels

Bamboo towels are a realistic choice for both home and resort utilization due to their reputation for being extraordinarily absorbent and speedy drying.

Curtains and Upholstery

Bamboo material is from time to time used for upholstery, pillows, and curtains in domestic décor. It has a sleek, present-day look and works well in phrases of durability and breathability.

Medical Textiles and Baby Products

Bamboo fabric is a safe choice for medical and toddler gadgets because of its antibacterial and hypoallergenic characteristics. Because it’s miles moderate on delicate pores and skin, it’s far ideal for:

Baby Clothes

Manufacturers frequently use bamboo fabric to create diapers, swaddling blankets, and onesies for toddlers. This fabric is ideal for babies because of its softness and natural resistance to allergens.

Medical Apparel

Reusable and Sustainable Products

Bamboo fabric is becoming more normal as reusable, environmentally pleasant objects for customers looking to reduce waste. Among the instances are:

Reusable Bags

Manufacturers create reusable shopping bags from bamboo material, making them a sustainable and environmentally friendly alternative to plastic bags.

Comparing Bamboo Fabric to Other Textiles

It is important to evaluate bamboo fabric with different extensively used fabrics like cotton, polyester, and silk so that it will completely recognize the advantages of cloth. While each fabric has its very own special features, bamboo regularly stands proud of its ability to mix sustainability, consolation, and adaptableness.

Bamboo Fabric vs. Cotton

Although cotton has long been a mainstay in textile manufacturing, bamboo material has some critical advantages over its herbal equivalent. First of all, in comparison to typical cotton cultivation, which makes use of several water and chemical substances, the bamboo cloth is considerably greater environmentally pleasant. Bamboo desires plenty less water and grows hastily without the usage of artificial fertilizers.

In terms of texture, is softer and smoother than cotton, making it ideal for people with sensitive skin. Additionally, bamboo fabric’s moisture-wicking and anti-bacterial properties outshine cotton, especially in activewear and bedding applications.

Bamboo Fabric vs. Polyester

Chemical producers like polyester look to synthetic materials for their affordability and durability. But as they manufacture polyester with petroleum-based chemicals, it is extremely environmentally damaging. Polyester cannot biodegrade so it becomes a part of the ever-expanding waste textile industry.

Bamboo fabric, however, breaks down naturally and is much more low-impact on the environment. Polyester can be strong, but bamboo cloth is more naturally strong, breathable and soft for eco-conscious buyers. Bamboo is also better than polyester at wicking moisture, making it a better fit for sports apparel and summer heat.

Bamboo Fabric vs. Silk

Silk is also prized for its high luster and comfort, but it is expensive (as well as morally questionable). Silkworms are commonly killed in conventional silk production, and animal rights activists have expressed alarm over the effects.

Bamboo fabric, particularly bamboo viscose, can offer a silk-like texture without the ethical dilemmas associated with silk production. It is much more affordable and sustainable, making it a popular alternative in the fashion industry. read more spandex fabric

Different Types of Bamboo Fabric

There isn’t always a single type of bamboo cloth that works for all packages; alternatively, there are several sorts with particular homes and production strategies. Although the primary function of all sorts of bamboo cloth is sustainability, manufacturing methods can affect the textures, longevity, and environmental friendliness of the cloth. Comprehending the wonderful varieties of bamboo cloth is important for making knowledgeable choices about garb, household textiles, or environmentally conscious merchandise.

Bamboo Viscose (Rayon)

Bamboo viscose, also called bamboo rayon, is the most widely used bamboo fabric. Designers weave it by chemical process, called the viscose method, where they soak bamboo in a solution to remove the cellulose. They then re-process the cellulose into fibers, and those fibers are spun into soft and smooth fabric.

Bamboo Linen

Bamboo linen is made using a machine as well, much like regular flax linen. Manufacturers smash the bamboo stalks, grind the fibres and spin them into yarn without using noxious chemicals. This technique produces a rough but incredibly sustainable cloth.

Bamboo Lyocell

Manufacturers make bamboo lyocell in a closed-loop system – more sustainable than the viscose process. In doing so, they dissolve the bamboo pulp with a harmless solvent and spin it into fibers. So the solvent is recycled and reused, so there is a lot less waste and bamboo lyocell is one of the most sustainable sources available. Bamboo lyocell also retains many of the same attributes as bamboo viscose but is less damaging to the environment.