Gabardine fabric stands out as one of the most classic textiles due to its durability, silky texture, and adaptability. Designers and manufacturers use it in everything from haute couture gowns to everyday casual robes, showcasing its versatility across fashion. This material maintains a strong presence in both formal and casual wear, effortlessly blending style with practicality. Its tightly woven structure offers remarkable strength, while the smooth finish provides a polished, refined appearance. Gabardine’s ability to resist wrinkles and repel water makes it a top choice for a wide range of garments, from elegant dresses to sturdy outerwear. Let’s explore what makes gabardine truly exceptional, including its uses, unique properties, and the intricate process behind its creation.

What is Gabardine Fabric?

Gabardine is a thick, twill-weaved fabric that features a diagonal rib on one side and a smooth surface on the other. Traditionally made of worsted wool, gabardine can be woven from cotton, polyester or some combination of these fabrics. The term “gabardine” originated with the late 19th-century Thomas Burberry, founder of the luxurious company Burberry, who marketed it as a waterproof material for outdoor use.

Properties of Gabardine Fabric

Gabardine fabrics are known for their unique blend of strength, softness, and elegance. Here are the primary features that differentiate it from other textiles:

1. Durability and Strength

But one of the most unique features of gabardine is its remarkable resilience. The cloth is tightly twill-woven, which gives it a dense, sturdy fabric that resists fading. This is why it’s a popular material for garments that need to be durable over time, like trousers, blazers, and uniforms.

2. Water-Resistance

Gabardine naturally resists water because it is a tight weave and does not let water penetrate through. It’s not waterproof, but it’s thick enough to withstand light rain and is great for trench coats and rain coats.

3. Wrinkle Resistance

Gabardine is much less prone to wrinkles than other fabrics, so it is often applied to suits and office uniforms. It keeps a high, sharp finish throughout the day, making it an economical option for both professionals and travellers..

4. Breathability

Gabardine, although extremely dense, has good breathability. Wool gabardine in particular draws air in and evaporates moisture from the skin. This makes it suitable for wear in a range of climates.

5. Smooth Texture

Gabardine has a flat, tight weave with a subtle diagonal rib on the front and a flat finish on the back. This silky texture gives the fabric a refined, stylish look suitable for both casual and formal wear.

6. Versatile Drape

Gabardine is moderately draping, which means that it doesn’t fall off your skin while still being a nice fit. This makes it an ideal fabric for suiting, skirting and jacketing, as it holds together without being stiff.

7. Resistance to Pilling and Abrasion

By its dense weave and high twist yarns, gabardine is impervious to pilling and abrasion. This keeps the fabric smooth and free of unpleasant fuzz, even when used repeatedly.

8. Heat Retention

Wool gabardine is a heat-sealing fibre that is ideal for colder conditions. It absorbs warmth, keeping the wearer warm in the winter. But gabardine made of cotton or polyester is lighter and suited to warmer climates.

9. Versatility in Fiber Composition

While gabardine is traditionally worsted wool, contemporary versions contain cotton, polyester and combinations of these materials. The properties of each type differ slightly:

Wool Gabardine: Light, luxurious and cozy.

Cotton Gabardine: Soft, breathable and summer-friendly.

Polyester Gabardine: Strong, wrinkle-resistant, and much less expensive.

10. Color Retention

Gabardine materials, particularly wool or cotton, are exceptionally colour-resistant. They soak up dye and retain deep, deep hues despite being washed and exposed to the sun over and again.

MANUFACTURING Process of Gabardine Fabric

Gabardine is carefully woven in such a way that it maintains its trademark strength, smooth surface, and signature twill pattern. From selecting the fibers to tailoring the fabric for the final application, each step enhances the fabric’s quality and versatility. Here’s an in-depth description of the gabardine cloth manufacturing process.

1. Fiber Selection

The key to making gabardine cloth is choosing the right fibers. Gabardine was traditionally knitted from worsted wool, a lustrous, smooth yarn that is strong and supple. But gabardine, in its contemporary form, can also be made of:

Cotton: Provides a light, breathable material for warmer weather.

Polyester: Adds durability, wrinkle protection, and water repellency.

Blends: Wool, cotton and polyester layered together to achieve different qualities such as warmth, toughness and cost.

The fiber choice also affects the final feel, weight, and breathable nature of the fabric.

2. Spinning the Yarn

Once selected, manufacturers weave the fibers into yarn using different spinning techniques based on the type of fiber. For wool gabardine, they comb worsted yarns to align the fibers parallel, eliminating short fibers in the process. This method creates a silky, high-twist yarn that gives wool gabardine its characteristic glossy sheen and elasticity. For cotton and polyester gabardine, they twist the fibers tightly to produce fine, sturdy yarns that form a dense, durable weave. The high-twist yarns in all types of gabardine enhance the fabric’s strength and improve its wrinkle resistance, making it both resilient and long-lasting.

3. Twill Weaving

The gabardine fabric has a diagonal rib weave and is thus distinctive for its twill weave. The weaving process involves:

Warp and Weft Threads: The warp (lengthwise) is tightly wound, and the weft (crosswise) threads are interwoven in a twill pattern.

Twill Construction: In this configuration, each weft goes under one or more warp threads and over two or more warp threads in a staggered manner. This gives us the gabardine lines.

The end product is a strong-wound fabric with a stiff, silky feel on the outside and a soft, flat texture on the inside.

4. Scouring and Cleaning

After weaving, manufacturers clean the cloth through a process called scouring, which removes natural oils, impurities, and chemicals from the fibers. They carefully dry the fabric to prepare it for dyeing and finishing. For wool gabardine, they use mild detergents and warm water to gently wash the fabric, preserving the softness of the wool fibers. In contrast, they clean cotton and polyester gabardine with stronger chemical treatments to effectively eliminate any waxes or residues, ensuring a clean and smooth surface for the next stages of production..

5. Fulling and Shrinking

The fabric is then fully pressed, a process of controlled shrinkage. This process further tightens the weave and increases the weight, durability, and resistance to water.

Fulling: involves dipping the fabric in water and using mechanical pressure to bring the fibres closer together.

Tightly Controlled Shrinking: Eliminates excessive shrinkage in subsequent washes and increases the fabric’s overall strength.

6. Dyeing and Color Finishing

Gabardine is dyed in numerous colours depending on its purpose. The process of dyeing varies depending on the fibre:

Wool Gabardine: Takes dye really deep, creating saturated colors.

Cotton Gabardine: Semi-matte finish with excellent color retention.

Polyester Gabardine: Usually dyed synthetically to produce intense, washable hues.

A handful of gabardine fabrics may also receive further colour enhancements — bleaching, printing or colour fixing — to enhance their beauty and durability.

7. Finishing Processes

After dying, the fabric undergoes finishing operations to increase its appearance, texture and performance:

Pressing: The fabric is pressed using heat and pressure to iron out wrinkles and give it a shiny crisp finish.

Waterproofing: Certain gabardine fabrics are treated with chemicals that make them more water-resistant if they are to be used as outerwear such as trench coats.

Anti-Pilling Treatment: Maintains smooth and wrinkle-free fabric in the long run.

8. Quality Control and Inspection

The fabric must be subject to rigorous quality controls before being placed into commercial use. This includes:

Weave Inspection: Verifying homogeneity in diagonal ribs and any imperfections or frayed threads.

Tensile Testing: Testing the fabric’s resistance to stretching and tearing.

Color Fastness: Making sure that the dye doesn’t fade and bleed when we wash.

Once the fabric passes these inspections, it is rolled and ready for distribution.

Uses of Gabardine Fabric:

Gabardine is admired for its durability, silky finish, and flexibility. These properties make it a popular product across industries, from fashion to practical outdoor equipment. For a complete rundown of the gabardine-cloth’s various applications, read on.

1. Fashion and Apparel

Gabardine is a ubiquitous material in fashion design, which is employed to make clothes that are both comfortable and stylish.

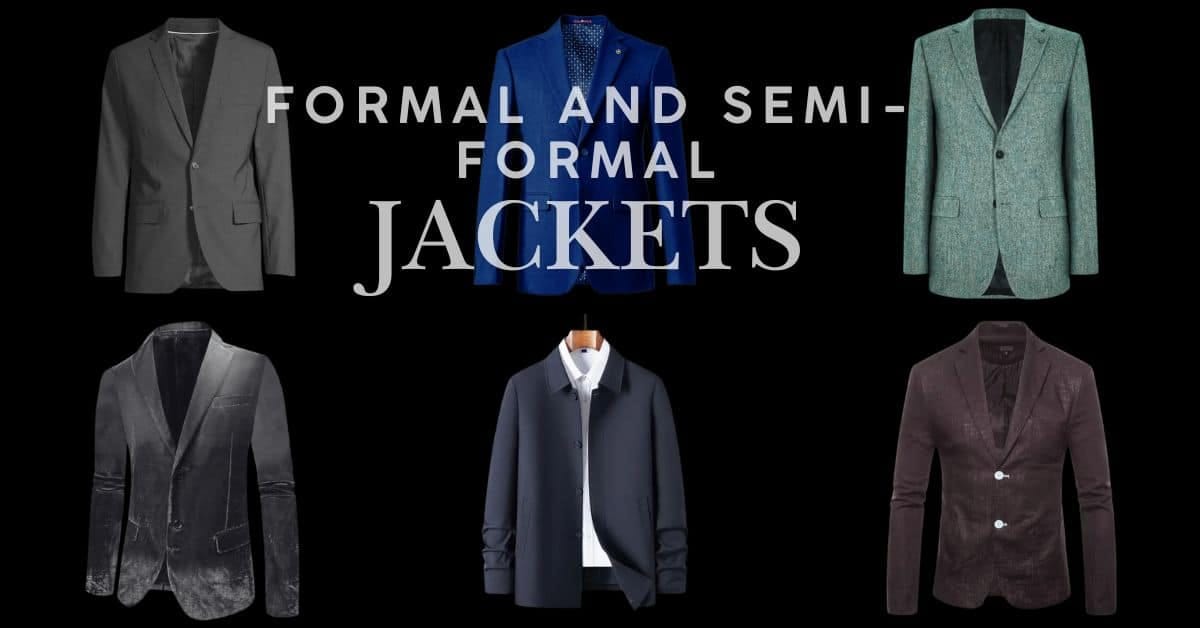

Suits and Blazers:

Gabardine’s clean, streamlined look is perfect for tailoring tailored suits and blazers. Because of its wrinkle-resistant and strong features, these clothing stays rigid and professional throughout the day.

2. Outerwear

But perhaps the most common uses of gabardine is for outerwear, where it’s best known for its toughness and resistance to water.

Trench Coats:

The most familiar use of gabardine is trench coats. Burberry’s founder Thomas Burberry introduced gabardine to the market for this use in the late 1800s. The fabric is water-repellent and perfect for repelling rain and wind.

3. Workwear and Uniforms

Gabardine is a standard fabric for uniforms and work wear because of its durability, toughness, and professionalism.

School Uniforms:

Gabardine is the most popular choice of school uniforms because it can withstand everyday use while remaining clean and tidy.

Military and Police Uniforms:

Gabardine is employed in military and police uniforms because it is tough, stain-resistant, and will retain creases so it will not discolour over the course of long wear.

4. Sportswear

Traditionally, gabardine was the preferred material for athletic wear because of its pliability and elasticity.

Golf and Equestrian Wear:

Throughout the early 20th century, gabardine became a common fabric for golf and horse clothes because it enabled mobility and protection against the elements.

5. Home Textiles

Less frequently, gabardine finds its way into household fabrics where longevity is crucial.

Upholstery:

Gabardine’s durable, finely knit construction makes it suitable for upholstery on furniture that sees frequent use.

Curtains and Drapery:

Because the fabric remains flexible and does not wrinkle, it is suitable for curtains and drapes in contemporary or minimalist rooms.

Types of Gabardine Fabric:

Gabardine fabric is available in various forms that vary in terms of properties depending on the fibre, weave density, and application. All styles possess the same diagonal twill weave but vary in texture, bulk and strength. By knowing what gabardine is available, you can select the right fabric for your situation.

1. Wool Gabardine

Description:

Wool gabardine is the most conventional and most expensive form of gabardine. It is fashioned from worsted wool, a yarn that is silky, fine and tightly twisted.

Key Features:

Comfy to touch and sophisticated in appearance.

Offers excellent durability and resilience.

Naturally wrinkle-resistant and breathable.

It is pretty well insulated and ideal for cooler areas.

Common Uses:

High-end suits and blazers.

2. Cotton Gabardine

Description:

It is a lightweight, breathable version of the fabric known as cotton gabardine. It retains the same twill pattern as wool but feels more relaxed and comfortable.

Key Features:

It’s lightweight and breathable, which is great for hot climates.

Comfortable against the skin.

It’s less wrinkle resistant than wool but is easier to maintain.

Offers moderate water resistance.

Common Uses:

Casual trousers and chinos.

Lightweight jackets and blazers.

Summer dresses and skirts.

3. Polyester Gabardine

Description:

Polyester gabardine, which is a synthetic version of the material, is more durable and resistant to wrinkles. It’s sometimes combined with other fibres, such as cotton or wool, to provide more versatility.

Key Features:

Very strong and resistant to scratches.

Great wrinkle resistance, easy to care for.

Water-resistant and quick-drying.

Cheaper than wool or cotton varieties.

Common Uses:

School uniforms, military uniforms, and business uniforms.

Work clothes, needing to be strong and clean.

4. Cotton-Polyester Blended Gabardine

Description:

This fabric offers the natural wicking characteristics of cotton and the durability and wrinkle-resistance of polyester. The blend proportion varies, and the softness and strength are different.

Key Features:

Balanced breathability and durability.

More wrinkle resistant than cotton.

Easy to clean, and washable.

Often cheaper than pure wool or cotton gabardine.

Common Uses:

Corporate uniforms and workwear.

Casual trousers and jackets.

5. Stretch Gabardine

Description:

Stretch gabardine is manufactured by combining elastane (spandex) with conventional fabrics such as cotton or polyester. This fabric adds a little extra stretch and comfort.

Key Features:

Gives a little stretch, which makes it easier to wear.

Maintains the traditional gabardine look.

Improved movement and mobility in sportswear or clothes.

Maintains durability and wrinkle resistance.

Common Uses:

Fitted trousers and skirts.

Fashionable office wear with comfort at heart.

Casuals, stretch chinos and jackets

Advantages of Gabardine Fabric:

Long-lasting: It is highly wear-resistant due to its thick weave.

Weather-resistant: Natural water repellent protects against mild rainfall.

Low-Heat Protection: Gabardine clothes need very little ironing and remain shapely.

Easy to wear: Both in casual and a business context.

Disadvantages of Gabardine Fabric:

Gabardine is not perfect, but it does come with some shortcomings:Consolidation: Wool gabardine retains heat, and is not recommended for hot climates.

Cost: Good gabardine, especially wool gabardine, is generally more expensive than other fabrics.

Limited Flexibility: The stiff weave limits its elasticity and may limit wear comfort for certain clothes.

Caring for Gabardine Fabric:

Washing

Wool gabardine should be dry-cleaned to preserve its texture and sculpture.

Clothes made of cotton and polyester can often be machine washed in cold water.

Drying

Wool gabardine should be air-dried flat to avoid shrinking.

Compounds can be tumble-dried at low temperature.

Ironing

Gabardine doesn’t wrinkle too much, though if you want you can iron it on a low-medium setting. You should use a pressing cloth to shield the surface of the cloth.

FAQS

What is gabardine cloth made of?

Gabardine, originally worsted wool, is now made from cotton, polyester and a combination of these fibres.

IS gabardine fabric waterproof?

Although not waterproof, gabardine, because of its tightly woven nature, is very resistant to water.

Is gabardine suitable for the summer season?

Cotton or polyester gabardine is ideal for warmer climates but wool gabardine is hot during summer.

Conclusion

Gabardine fabric continues to symbolize elegance, utility and resilience. Whether in suits or rugged jackets, its unique qualities lend it to many uses. You will know what it is, how it is used, and how it is treated so you can make the right choice when you decide to invest in gabardine clothing for your home.

2 thoughts on “What is Gabardine Fabric? Properties, Uses, and Manufacturing?”

Isı transfer yüzeyi Petek temizliği yaptırmak hiç bu kadar kolay olmamıştı. Ekip Tesisata teşekkürler!

BWER Company is Iraq’s leading supplier of advanced weighbridge systems, offering reliable, accurate, and durable solutions for industrial and commercial needs, designed to handle heavy-duty weighing applications across various sectors.