Velour fabric is synonymous with luxury, comfort, and versatility. Famous for its plush texture and elegant appearance, velour has been a favorite across the fashion, home decor, and performance arts industries for ages. But what makes velour fabric unique? How is it created, and why is it so widely used? All aspects of velour fabric, including its properties, applications, and the intricate processes involved in its manufacture, are discussed in this article

Introduction to Velour Fabric

Velour fabric is a soft, stretchy, and durable textile known for its velvet-like appearance. It is a pile fabric, meaning it has a raised surface of fibers that lends a plush feel. Derived from the French word “velours,” meaning velvet, velour mimics the luxurious appearance of velvet but is often more affordable and versatile.

Velour fabric combines softness, shine, and durability, making it a cherished choice for many. Crafted primarily from cotton or synthetic fibers like polyester, it brings a sense of opulence and coziness to both clothing and upholstery.

Table of contents

- Introduction to Velour Fabric

- What is Velour Fabric?

- The Origins and History of Velour Fabric

- Manufacture process of Velour Fabric:

- Properties of Velour Fabric

- Uses of Velour Fabric

- Velour vs velvet fabric.

- Advantages of Velour Fabric

- Disadvantages of Velour Fabric

- How to Care for Velour Fabric

- Why is Velour Fabric Popular?

- Sustainable Velour: A Growing Trend

- Conclusion

- What is Suede Fabric?

- FAQs

What is Velour Fabric?

Velour is known as knit or woven cloth that contains a dense pile of cut loops. These cut loops create its soft finish, just like velvet. However, whereas silk or high grade fibers create velvet, more readily accessible materials make up the fabric that is velour.

Velour fabric flexibility also results from the ability to compose with several other fibers, like cotton, polyester, and spandex, to create added strength, stretch, and moisture-wicking properties, which allow for diverse application.

The Origins and History of Velour Fabric

Velvet has its roots in ancient textile traditions as plush, textured material is representative of luxury. When aristocratic fashion was dominated in Europe by velvet, this more accessible material came onto the scene during the 19th century with a name derived from the French velours, meaning velvet.

Velour has been a mass-market fabric due to advancements in knitting technology during the 20th century. Its use gained popularity with the emergence of tracksuits in the 1970s and has since become a staple fabric for

various industries.

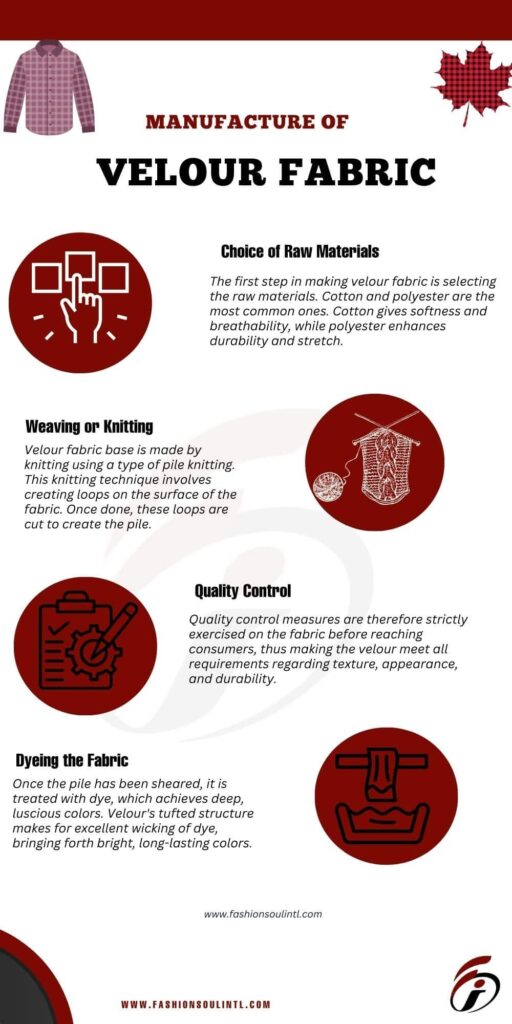

Manufacture process of Velour Fabric:

Velour fabric production requires a lot of intricate techniques and skillful craftsmanship. This multi-step process ensures that the material remains soft, stretchy, and visually appealing.

1. Choice of Raw Materials

The process of making velour fabric begins with selecting the raw materials. Manufacturers commonly choose cotton for its softness and breathability and polyester for its durability and stretch. To combine the benefits of both, they sometimes use a blend of these two fibers.

2. Weaving or Knitting

Velour fabric base is made by knitting using a type of pile knitting. This knitting technique involves creating loops on the surface of the fabric. Once done, these loops are cut to create the pile. Density and length of the loops result in varying softness and thicknesses of the final fabric.

3. Cutting the Pile

The loops from knitting are carefully cut off, which forms velour’s iconic short pile. Precision at this step ensures a fair surface with consistent texture, and cut pile is the material that provides velour its plush feeling, almost velvety.

4. Dyeing the Fabric

Once the pile has been sheared, it is treated with dye, which achieves deep, luscious colors. Velour’s tufted structure makes for excellent wicking of dye, bringing forth bright, long-lasting colors.

5. Finishing Touches

The finishing process typically includes treatments for softening, durability, and enhancing the sheen of velour. Manufacturers may further apply protective coatings for stain-resistance and colourfastness.

6. Quality Control

Quality control measures are therefore strictly exercised on the fabric before reaching consumers, thus making the velour meet all requirements regarding texture, appearance, and durability.

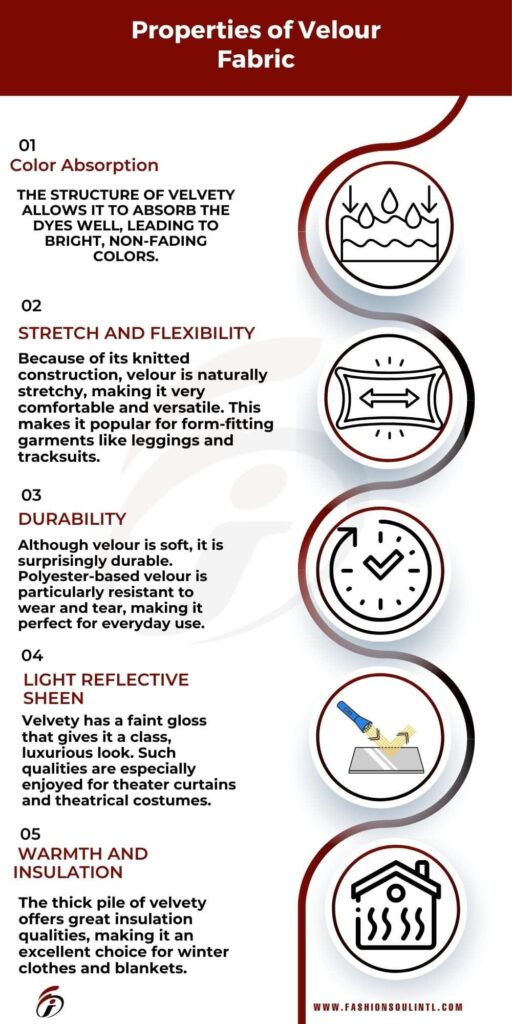

Properties of Velour Fabric

Velour fabric is very desirable because it has unique properties. So, let’s look into the key characteristics that can set it apart:

1. Plush Texture

A velour is characterized by having a soft and plush surface. The short-pile surface is smooth to touch, making it ideal for clothing, upholstery, or decor.

2. Stretch and Flexibility

Because of its knitted construction, velour is naturally stretchy, making it very comfortable and versatile. This makes it popular for form-fitting garments like leggings and tracksuits.

3. Durability

Although velour is soft, it is surprisingly durable. Polyester-based velour is particularly resistant to wear and tear, making it perfect for everyday use.

4. Light Reflective Sheen

A faint gloss gives velvety fabric its classy, luxurious look. These qualities make it especially popular for theater curtains and theatrical costumes

5. Warmth and Insulation

The thick pile of velvety offers great insulation qualities, making it an excellent choice for winter clothes and blankets.

6. Color Absorption

The structure of velvety allows it to absorb the dyes well, leading to bright, non-fading colors.

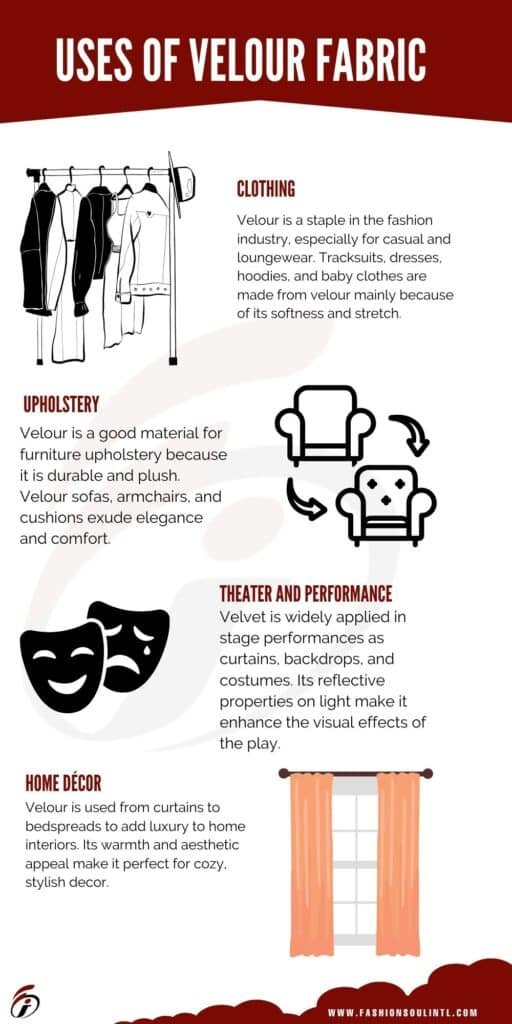

Uses of Velour Fabric

One of the greatest strengths of velour fabric is its versatility. Here are some of the most common uses for this plush material:

1. Clothing

Velour is a staple in the fashion industry, especially for casual and loungewear. Tracksuits, dresses, hoodies, and baby clothes are made from velour mainly because of its softness and stretch.

2. Upholstery

Velour is a good material for furniture upholstery because it is durable and plush. Velour sofas, armchairs, and cushions exude elegance and comfort.

3. Home Decor

Velour is used from curtains to bedspreads to add luxury to home interiors. Its warmth and aesthetic appeal make it perfect for cozy, stylish decor.

4. Theater and Performance

Velvet is widely applied in stage performances as curtains, backdrops, and costumes. Its reflective properties on light make it enhance the visual effects of the play.

5. Automotive Interiors

Automobile seat covers, headrests, and door linings are covered with velour for comfort and style.

6. Accessories

Velvet is applied in fashionable accessories such as hats, scarves, and handbags, which add a soft, stylish touch.

7. Crafts and DIY Projects

Velour is adored by craft enthusiasts who use it to make plush toys, decorative pillows, and other handmade items. Its softness and colorful hues make it a favorite for DIY projects.

Velour vs velvet fabric.

| Aspect | Velour | Velvet |

|---|---|---|

| Texture | Plush and slightly stretchy, making it comfortable for casual wear and practical use. | Dense and less stretchy, giving it a more refined and luxurious feel. |

| Material | Often made from polyester or cotton, making it durable and easy to maintain. | Typically made from silk, rayon, or polyester, contributing to its rich texture and high-end appeal. |

| Cost | More affordable due to simpler production techniques and materials. | More expensive, especially when made with silk, due to the intricate weaving process. |

Advantages of Velour Fabric

There are several advantages that come with choosing velour:

- Affordability: Velour is cheaper than velvet.

- Versatility: It’s mostly adaptable to any use-from fashion to home decoration.

- Comfort: The softness and stretch make velour garments incredibly comfortable.

- Low Maintenance: Velour is relatively easier to maintain than velvets, especially in synthetic versions.

Disadvantages of Velour Fabric

While velour has many virtues, it is not entirely free of vice:

- Prone to Pilling: The fabric pile will pill with time, mostly due to heavy usage.

- Heat Sensitivity: Synthetic velour can melt or shrink if exposed to high heat.

- Dust Accumulation: It tends to attract dust and lint, and it requires regular cleaning.

How to Care for Velour Fabric

Proper care is important to keep velour-looking beautiful:

- Washing: Only use cold water and a mild detergent. Do not use harsh chemicals or bleach.

- Drying: Air-dry velour whenever possible. If using a dryer, use the lowest heat setting.

- Ironing: Turn the garment inside out and iron on low.

Velour is always soft, vibrant, and long-lasting with regular maintenance.

Why is Velour Fabric Popular?

The reason why velour fabric is very popular is due to its luxurious feel, affordability, and versatility. The ability to mimic the feel of velvet at a fraction of the cost makes it very attractive to designers as well as consumers. Comfort and stretchability enhance the desirability of the fabric for casual and athleisure wear.

Sustainable Velour: A Growing Trend

With sustainability at the forefront, eco-friendly velour is increasingly in demand. Velour is now made from organic cotton or recycled polyester, making it more environmentally friendly. This is in line with the rising demand for sustainable textiles in fashion and home goods.

Read more about mesh fabric.

Conclusion

Velour fabric is a remarkable material that combines elegance, comfort, and functionality. Its unique properties and affordability make it a favorite across industries, from fashion to furniture. By understanding velour’s properties, making process, and uses, you can appreciate why it remains a timeless choice for consumers and designers alike.

What is Suede Fabric?

Suede is one of the most loved fabrics in the textile world. It surrounds us all the time and holds an extraordinary place in fashion, upholstery, and accessories because of its quality, unique look, and outstanding versatility. But what exactly makes suede? Why do people often associate cashmere with luxury, and what makes it so special? This article explores suede fabric, its properties, its uses, and the process behind its creation. You’ll also learn how to care for suede and discover more eco-friendly alternatives to this timeless material.

FAQs

Manufacturers make velour fabric from natural fibers like cotton or synthetic materials such as polyester.

No, velour and velvet differ in texture, production methods, and cost.

Velour is not ideal for outdoor use as it’s prone to moisture absorption and fading.